Design For Manufacturing

Design For Manufacturing To Optimize Product Development

Design for manufacturing service we provide is a critical method that helps us to focus on your custom products with manufacturing efficiency in mind. This Design for manufacturing service will be suitable for any manufacturing processes from plastic/metal injection, forging and casting and we will elaborate more this design for manufacturing step by step to bring you more clear understanding how we review, optimize and quickly feedback to ensure your custom products are designed with proper manufacturing consideration right from the very beginning. For more information, please review the following detailed explanation:

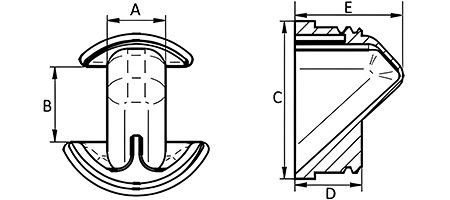

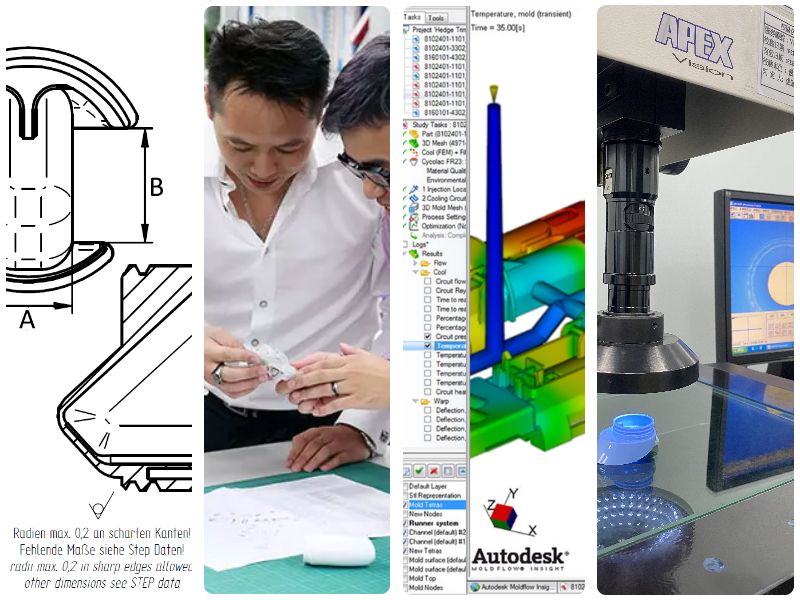

2D Drawing Review

First step for our design for manufacturing is to review your custom 2D drawing which is a critical way to evaluate your drawings to ensure they are optimized for efficient and cost-effective manufacturing, also will go thoroughly the tolerance and geometric tolerance to make sure your custom design will be appropriate for the final functional requirements.

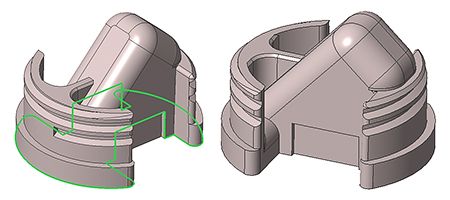

Molding Structure Checking

Analyzing your design by our design for manufacturing and we will quickly provide further feedback such as proper location of the Parting Line and Gate as well as the Type of the injection gate so that those marks could be hidden to have better aesthetic on the outward.

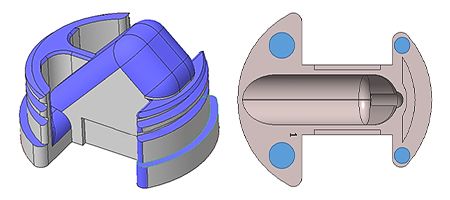

De-molding evaluation

To avoid the undrafted part will have higher success rate during de-molding process. Therefore, we will review and calculate the proper draft angle for you and will also recommend the location for the Ejector Pin in our design for manufacturing so that you will understand how we leave those marks inwards.

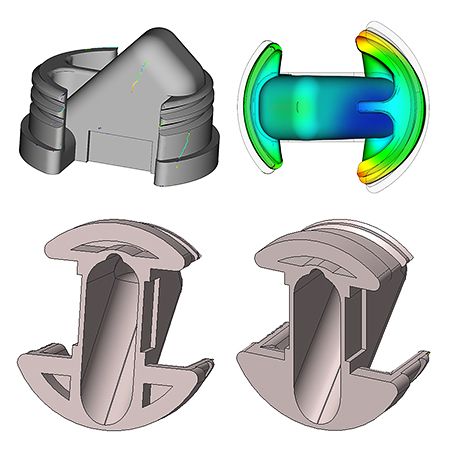

Mold Flow Analyzing For Other Potential Issues

Undercut will affect any manufacturing parts ejected from the molds and shall be avoided while designing. If it is inevitable then we will need to use Sliders or redesign the structure of tooling in order to run the manufacturing smoothly. Except from that, our engineering team will have mold flow analyzing for your custom items to foresee any potential issues and quick feedback to let you know if there is any possibility of having Sink Marks, Welding Line, Warping or Deformation on the appearance of your parts, so we will review your design thoroughly then provide final summary for your custom parts in our design for manufacturing feedback.

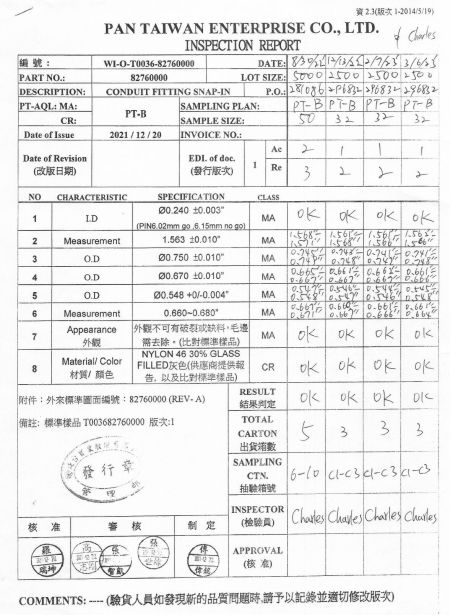

Quality inspection for your custom parts

All dimension of your custom parts will be documented when first sample is ready and we will go through with you how and where to measure your parts so that our quality control team will inspect it based on that, like basic dimension by calipers, 2.5D optical measurement equipment to inspect the critical size of your delicate and complicated custom items, using spectrometer to check the colors on appearance and functional test on the mating parts your provided and apart from that, we will keep every sample in our sample archive for each batch just in case if discussion needed in the future and if necessary, we will also provide the material/inspection report for your custom parts.

Tooling Maintenance

Tooling maintenance is a crucial indication to make sure the optimal performance and longevity for your molds. For example, the material for plastic injection tooling, usually we will use AISI P20 if there is no specific requirement on the surface of plastic parts. The material of plastic injection tooling P20 could be guaranteed to reach 200,000 shots of molding and will have major maintenance per 50,000 shots of molding but actually we also do basic maintain after each productions so that to keep the life span of tooling a bit longer. We will keep monitoring the molding shots and inspect the plastic injection tooling when it comes to 200,000 shots of molding to see if this tooling is still workable or not then notify you the final tooling status.

If any new developing parts are verified for manufacturing and waiting for further cost evaluation, please contact Pan Taiwan without hesitation and our sales representative will follow up the discussion with you in a working day!