Forging

Customized forgings

Pan Taiwan is a leading forging manufacturer with decades of experience supplying precision‑engineered components to industries worldwide — from marine hardware, bicycle and motorcycle accessories, to medical devices and automotive parts. Our advanced forging capabilities allow us to deliver products in a wide range of sizes, shapes, and material properties, tailored to meet your exact design, performance, and compliance requirements.

Whether you need a custom prototype or high‑volume production, our team works closely with you from concept to completion, ensuring quality, reliability, and cost efficiency at every stage. If you have a design ready to make real, partner with Pan Taiwan today and turn your vision into reality.

THE MATERIALS BELOW ARE IDEAL FOR THE FORGING PROCESS

- Alloy Steel: Engineered for high strength and fatigue resistance in demanding industrial applications

- Aluminum: Lightweight and corrosion-resistant; ideal for marine, automotive, and consumer-grade components

- Carbon steel: Cost-effective and durable; suitable for structural and load-bearing parts

- Stainless steel: High corrosion resistance and hygiene compliance; used in medical, food-grade, and outdoor gear

- Copper: Excellent thermal and electrical conductivity; forged for precision connectors and specialty fittings

Pan Taiwan offers comprehensive vertical and horizontal integration services to meet diverse manufacturing needs. Our capabilities cover the entire production cycle — from product design consultation and manufacturing feedback, to precision tooling development, forging and machining processes, heat treatment, surface finishing, and final quality inspection.

With a highly skilled team committed to professional service and manufacturing excellence, we can also integrate multiple production methods to create complex parts, assemble complete products, and provide custom packaging solutions ready for shipment.

Application

- Marine hardware: Corrosion-resistant forged components for harsh offshore environments

- Bike accessories: Lightweight, precision forged parts for performance and durability

- Motorcycle industry: High-strength structural and aesthetic parts for OEM and aftermarket

- Medical products: Precision forged parts supplied for medical device assemblies, subject to client-specific quality protocols

- Auto parts: Safety-critical components forged to meet global compliance standards

Here's a simple comparison between hot and cold forging to help you understand their key differences before exploring further!

Hot forging is performed at high temperatures, making it ideal for shaping complex forms and handling tougher materials, though it may result in lower precision and a rougher finish. Cold forging, on the other hand, is done at room temperature and offers better dimensional accuracy and a cleaner surface, making it suitable for parts that require tight tolerances. To learn more about specific information, please scroll down and learn more!

Hot Forging

Hot forging is a precision forming process where metal is shaped under intense heat, typically...

DetailsCold Forging

Cold forging is a precision metal forming process performed at or near room temperature. It involves...

DetailsForging Manufacturer | Pan Taiwan

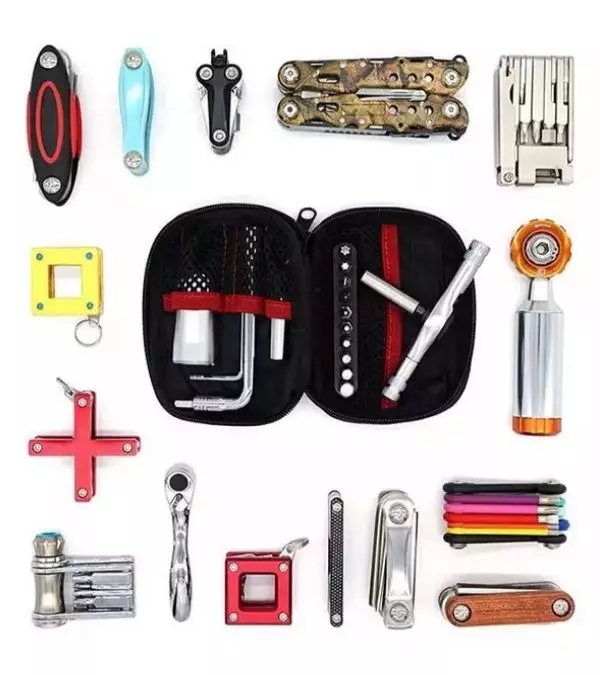

Located in Taiwan since 1977, Pan Taiwan Enterprise Co., Ltd. has been a manufacturing process services provider. Our main manufacturing process services include, Forging, tactical bags manufacturing, custom bike frames, custom carbon fiber products, multi-tools, custom plastic injection parts, product assembly, reverse engineering, investment casting parts, machined parts, sheet metal stamping, bike caps, which have ISO 9000 and ISO 13485 quality assurance certifications.

Pan Taiwan with certified ISO 9001 provides manufacturing services and total solutions for anyone who has any custom parts in need we have sophisticated experiences to partner with a wide range of manufacturers from Plastic Injection, Die Casting, Forging, CNC machining, Tactical Bags, EDC pouches or standard bicycle and outdoor activity parts for nearly 50 years, so we will act as your eyes and ears for any project you have with us. We don't just supply bicycle parts, accessories, and carabiners in multiple applications. We also offer OEM and ODM services to make your idea come true. The manufacturing processes we're good at are plastic injection, sheet metal stamping, investment casting, MIM and many more.

Pan Taiwan has been offering customers manufacturing process services, both with advanced technology and 50 years of experience, Pan Taiwan ensures each customer's demands are met.