Hot Forging

Hot forging is a precision forming process where metal is shaped under intense heat, typically above its recrystallization point, to achieve superior mechanical integrity and complex geometries. Unlike cold forging, this method leverages thermal plasticity to reduce resistance during deformation, allowing for smoother material flow and stronger internal grain alignment. It's a go-to solution for industries demanding high load performance, such as automotive, aerospace, defense, and heavy machinery. By combining elevated temperatures with controlled force, hot forging enables manufacturers to produce components that are not only structurally robust but also optimized for fatigue resistance and long-term durability.

The advantages of hot forging are as below

- Improved Material Flow: High temperatures allow better deformation, ideal for intricate shapes.

- Enhanced Mechanical Properties: Refined grain structure increases strength, toughness, and fatigue resistance.

- Reduced Work Hardening: Less stress on tooling and machinery compared to cold forging.

- Versatility in Material: Suitable for steel, stainless steel, titanium, aluminum, and nickel alloys.

- Scalability: Efficient for medium to high volume production with consistent quality.

The disadvantages of hot forging are as below

- Dimensional Tolerance Limits: Less precise tolerance due to thermal contraction and warping; secondary machining often required.

- Surface Oxidation: Undesirable reactions with the atmosphere may cause scaling or surface defects if not properly controlled.

- Grain Structure Variation: Grain structure may vary throughout the metal due to uneven cooling or metallurgical factors.

- Higher Energy Consumption: Requires heating systems and temperature control; dies may degrade faster due to thermal stress.

Hot Forging Manufacturer | Pan Taiwan

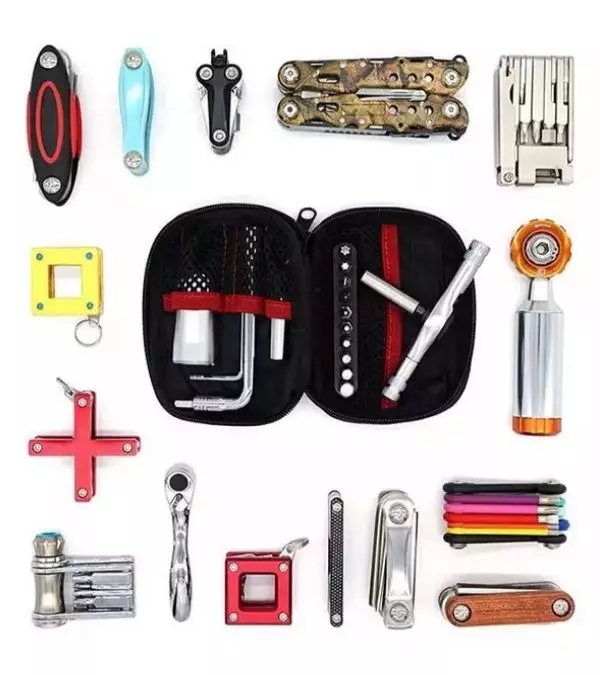

Located in Taiwan since 1977, Pan Taiwan Enterprise Co., Ltd. has been a manufacturing process services provider. Our main manufacturing process services include, Hot Forging, tactical bags manufacturing, custom bike frames, custom carbon fiber products, multi-tools, custom plastic injection parts, product assembly, reverse engineering, investment casting parts, machined parts, sheet metal stamping, bike caps, which have ISO 9000 and ISO 13485 quality assurance certifications.

Pan Taiwan with certified ISO 9001 provides manufacturing services and total solutions for anyone who has any custom parts in need we have sophisticated experiences to partner with a wide range of manufacturers from Plastic Injection, Die Casting, Forging, CNC machining, Tactical Bags, EDC pouches or standard bicycle and outdoor activity parts for nearly 50 years, so we will act as your eyes and ears for any project you have with us. We don't just supply bicycle parts, accessories, and carabiners in multiple applications. We also offer OEM and ODM services to make your idea come true. The manufacturing processes we're good at are plastic injection, sheet metal stamping, investment casting, MIM and many more.

Pan Taiwan has been offering customers manufacturing process services, both with advanced technology and 50 years of experience, Pan Taiwan ensures each customer's demands are met.