Carbon Fiber Parts Manufacturing

Carbon Fiber Parts Manufacturing, OEM Solutions by Pan Taiwan

At Pan Taiwan, we specialize in carbon fiber part manufacturing tailored for OEM applications across automotive, industrial, and sporting sectors. Our in-house equipment and process control enable six core forming methods – filament winding, roll wrapping, pultrusion, compression molding, hand lay-up, and vacuum bagging- giving us the flexibility to meet complex design and performance requirements. Whether you’re developing lightweight structural components or precision-engineered tubes, our multi-process capability ensures consistent quality and production efficiency.

From Tubes to Panels: What We Can Build

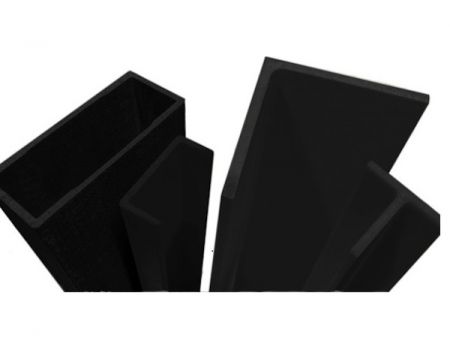

Our facility is equipped to handle a wide range of carbon fiber forming scenarios. We produce cylindrical tubes up to 3200mm in length using dry filament winding, and offer roll wrapping for smaller diameters with smooth surface finishes. For structural panels and molded covers, our compression molding system operates at temperature up to 400°C with mold sizes reaching 1000 * 1000mm. Curved surfaces and custom geometries are supported through hand lay-up and vacuum bagging, backed by thermal ovens and demolding systems. Every stage – from cutting to refrigerated prepreg storage is managed in-house for full traceability and control.

Integrated Systems for Scalable Manufacturing

Unlike fragmented supply chains, Pan Taiwan brings all major carbon fiber forming processes under one roof. This integration allows us to rapidly shift between prototyping and mass production, while maintaining consistent quality through ISO 9001-certified documentation and inspection. Our tooling flexibility, long-shaft forming capability, and high–temperature molding systems make us a reliable partner for OEMs seeking precision, speed, and adaptability in carbon fiber manufacturing.

Custom Carbon Fiber Components, Engineered for Performance

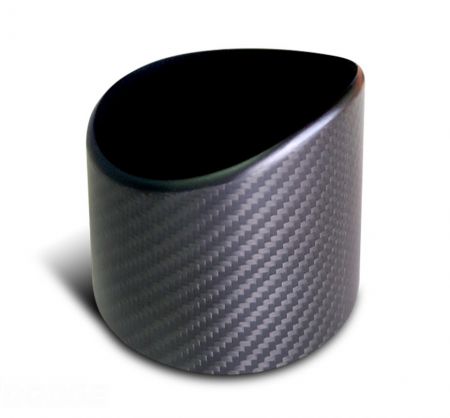

We manufacture a wide variety of carbon fiber parts – from strut bars and hydrofoil shafts to battery covers, bike frames, and exhaust pipe end caps. Each component is matched to the most suitable forming method based on its geometry, strength requirements, and surface finish goals. Available finishes include 3K, 12K, UD, dye sublimation, and cloth implant, allowing us to meet both functional and aesthetic demands. Our engineering team ensures that every part delivers optimal performance with minimal weight.

Your Strategic Partner in Carbon Fiber OEM Manufacturing

Choosing Pan Taiwan means gaining access to up to 60% weight reduction compared to metal parts, superior shock absorption, corrosion resistance, and low thermal expansion – all critical for precision assemblies. Our in-house tooling and multi-process flexibility shorten lead times and simplify complex OEM workflows. Let us help you turn your carbon fiber concept into a production-ready solution. Contact us today to discuss your project, request a quote, or explore our forming capabilities.

Roll Wrapping

Carbon fiber tube in Pan Taiwan are made by roll wrapping, this manufacturing process is typically...

DetailsFilament Winding

Thanks to the characteristic of the filament winding, Pan Taiwan(OEM) can not only manufacture...

DetailsPultrusion

If you are looking for a supplier for high quality carbon fiber parts in straight shape, you are looking...

DetailsCompression Molding

There are many fabrication processes to create carbon fiber parts, here at Pai Taiwan(OEM),...

DetailsHand Lay-up Process

Pan Taiwan provides custom carbon fiber manufacturing process - hand lay-up process. Hand lay-up...

DetailsVacuum Bagging

Pan Taiwan provides custom carbon fiber parts made by vacuum bagging. The mold cost is lower...

DetailsCarbon Fiber Parts Manufacturing Manufacturer | Pan Taiwan

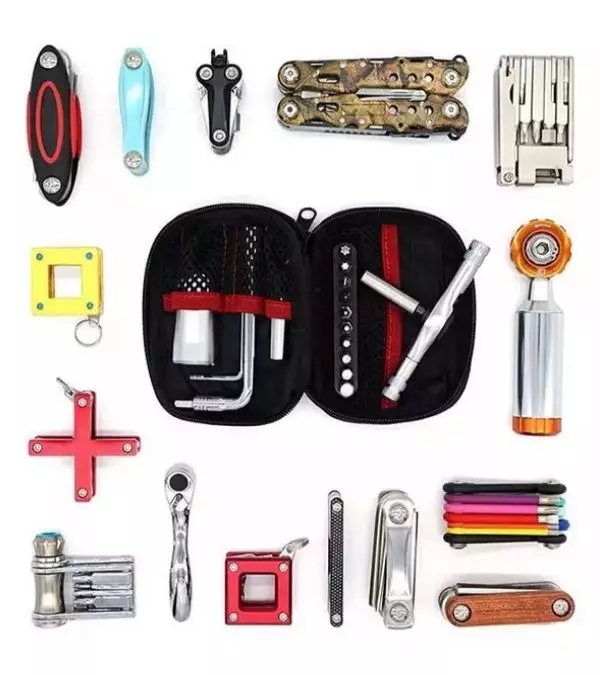

Located in Taiwan since 1977, Pan Taiwan Enterprise Co., Ltd. has been a manufacturing process services provider. Our main manufacturing process services include, Carbon Fiber Parts Manufacturing, tactical bags manufacturing, custom bike frames, custom carbon fiber products, multi-tools, custom plastic injection parts, product assembly, reverse engineering, investment casting parts, machined parts, sheet metal stamping, bike caps, which have ISO 9000 and ISO 13485 quality assurance certifications.

Pan Taiwan with certified ISO 9001 provides manufacturing services and total solutions for anyone who has any custom parts in need we have sophisticated experiences to partner with a wide range of manufacturers from Plastic Injection, Die Casting, Forging, CNC machining, Tactical Bags, EDC pouches or standard bicycle and outdoor activity parts for nearly 50 years, so we will act as your eyes and ears for any project you have with us. We don't just supply bicycle parts, accessories, and carabiners in multiple applications. We also offer OEM and ODM services to make your idea come true. The manufacturing processes we're good at are plastic injection, sheet metal stamping, investment casting, MIM and many more.

Pan Taiwan has been offering customers manufacturing process services, both with advanced technology and 50 years of experience, Pan Taiwan ensures each customer's demands are met.