Filament Winding

Thanks to the characteristic of the filament winding, Pan Taiwan(OEM) can not only manufacture round tube but also shaped tube according to customer's requirements.

The filament winding process begins with a tow of carbon fiber, fiberglass or carbon fiber-fiber glass hybrid. The tow is put on the spools at the winding machine. There is a mandrel that is at the front of the spools.

This process involves winding filaments under tension over a rotating mandrel. The mandrel rotates around the spindle while a delivery eye on a carriage traverses horizontally in line with the axis of the rotating mandrel, laying down fibers in the desired pattern or angle. Once the mandrel is covered with desired thickness, it will be placed in the oven for curing. After the resin is cured, the mandrel is removed, leaving the hollow final product.

With our thin ply tech, multiple thin layered film construction using CF and AL or selected fiber layer, low FAW CF ply combined with AL foil or selected fiber backing, the product is strong and lightweight. Our engineers will work closely with your company to develop and meet performance specifications. Get you project started with us.

What applications are suitable to use filament winding?

The limit on filament winding is lower compare to roll wrapping. So curved tubing like bicycle handlebar is achievable. The applications like golf, bicycle forks, bicycle rims, power and transmission poles, and sailing masts are suitable to use filament winding.

Filament Winding Manufacturer | Pan Taiwan

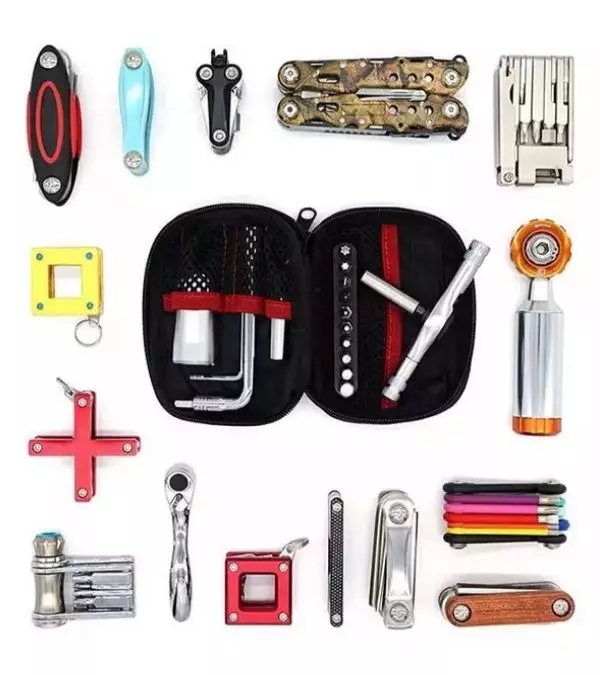

Located in Taiwan since 1977, Pan Taiwan Enterprise Co., Ltd. has been a manufacturing process services provider. Our main manufacturing process services include, Filament Winding, tactical bags manufacturing, custom bike frames, custom carbon fiber products, multi-tools, custom plastic injection parts, product assembly, reverse engineering, investment casting parts, machined parts, sheet metal stamping, bike caps, which have ISO 9000 and ISO 13485 quality assurance certifications.

Pan Taiwan with certified ISO 9001 provides manufacturing services and total solutions for anyone who has any custom parts in need we have sophisticated experiences to partner with a wide range of manufacturers from Plastic Injection, Die Casting, Forging, CNC machining, Tactical Bags, EDC pouches or standard bicycle and outdoor activity parts for nearly 50 years, so we will act as your eyes and ears for any project you have with us. We don't just supply bicycle parts, accessories, and carabiners in multiple applications. We also offer OEM and ODM services to make your idea come true. The manufacturing processes we're good at are plastic injection, sheet metal stamping, investment casting, MIM and many more.

Pan Taiwan has been offering customers manufacturing process services, both with advanced technology and 50 years of experience, Pan Taiwan ensures each customer's demands are met.