Powder Metallurgy

Sintering

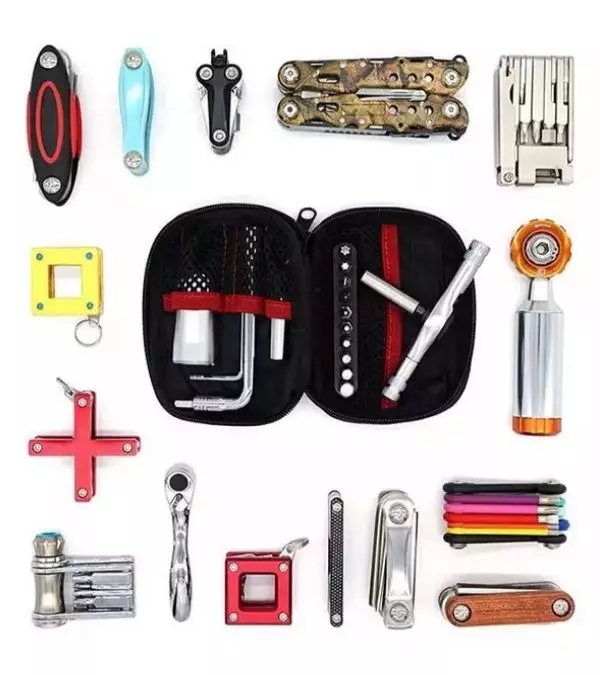

Pan Taiwan, as a leading subcontract manufacturer in power metallurgy process field, has partnered with customers for numerous OEM projects and achieved countless delicate pieces. Along with continuous technology innovation, its advantages of powder metallurgy in complex contours, high strength, consistent quality, and most importantly lower cost without secondary process are often adopted as first priority in engineering. Power metallurgy technology is wild used in diversified categories. Applications are enormous, including transmission gears, clutch parts, sprockets, mill parts, etc.

Pan Taiwan owns its R&D team with 8 members to review drawing, analyze design feasibility, structure of molds, material selection upon product applications. We are not just an OEM contract manufacturing, but devoted to help customers solve their design problem. In addition, some customers may be concerned about MOQ issue upon different product applications. We are flexible to offer different packaging quotes to meet customers' need.

At last, our tenet is to provide vertical and horizontal integration services and bring an thorough comfortable and reliable shopping experiences to you. From design feedback, tooling development, efficient production management, Pan Taiwan team is ready to serve you with our professionalism.

Powder Metallurgy Manufacturer | Pan Taiwan

Located in Taiwan since 1977, Pan Taiwan Enterprise Co., Ltd. has been a manufacturing process services provider. Our main manufacturing process services include, Powder Metallurgy, tactical bags manufacturing, custom bike frames, custom carbon fiber products, multi-tools, custom plastic injection parts, product assembly, reverse engineering, investment casting parts, machined parts, sheet metal stamping, bike caps, which have ISO 9000 and ISO 13485 quality assurance certifications.

Pan Taiwan with certified ISO 9001 provides manufacturing services and total solutions for anyone who has any custom parts in need we have sophisticated experiences to partner with a wide range of manufacturers from Plastic Injection, Die Casting, Forging, CNC machining, Tactical Bags, EDC pouches or standard bicycle and outdoor activity parts for nearly 50 years, so we will act as your eyes and ears for any project you have with us. We don't just supply bicycle parts, accessories, and carabiners in multiple applications. We also offer OEM and ODM services to make your idea come true. The manufacturing processes we're good at are plastic injection, sheet metal stamping, investment casting, MIM and many more.

Pan Taiwan has been offering customers manufacturing process services, both with advanced technology and 50 years of experience, Pan Taiwan ensures each customer's demands are met.