Surface Treatment

Electroplating, electroless plating surface treatment

Pan Taiwan offers surface treatments applied to auto parts, decorative parts, fashion accessories, bicycle parts, lighting equipment, and industrial parts for anti-corrosion purpose, such as automotive parts. Our expertise in fabrication processes makes us capable of handling each component’s finish treatment according to its application and environment.

Also, we are able to offer our clients different services, such as electroplating, electroless plating, anodizing, hard anodizing, chemical treatment oxidation, hot dipping, vacuum plating, painting, thermal spraying, surface hardening, heat treatment, ti colorization, Teflon coating as well as trivalent chromium passivation.

Regardless of the material, such as steel, aluminum, brass, titanium, etc. and even plastic, we are capable of arranging the suitable process for your products!

Fully-equipped Background

Our suppliers are all over Taiwan, and they possess a broad range of equipment as below. Besides that, we can arrange the suitable supplier according to your products. And in case there’s any emergency, since our good relation with so many suppliers, we can assist you to find another plant to make the production work smoothly.

- Bench grinders

- Electroplating machines

- PVD / CVD deposition machines

- All kinds of spray guns

- Blast cabinets

- Downdraft tables

- Scalers

- Sanders

Going Through the Adhesion Testing

Each of the items has passed the adhesion testing and has better resistance to the friction and scratch. The adhesion testing is a valuable indicator for determining how well paints and coatings are bonded to the substrate on which they are applied. If the products fail to remain intact and adherent to the substrate, they may lead to serious operation issues with economic losses. To prevent this situation, we have to thoroughly examine the products.

When it comes to our quality assurance, you are welcome to apply for the international standard tests, e.g. ASTM B-17, the salt spray test, to see whether the products could resist the corrosion, or SPI-AQ-103, to find out if there’s anything wrong with the surface.

Your Products Would Get Better With Our Assistance.

From defining the right material, choosing the suitable manufacturing process and opting the most efficient surface treatment to optimize your products, we take every step seriously. On top of that, we also care about your satisfaction towards the products, and therefore, our clients are willing to have further cooperation with us. We are happy to cooperate with you on the surface treatment projects, let me know if you have any questions.

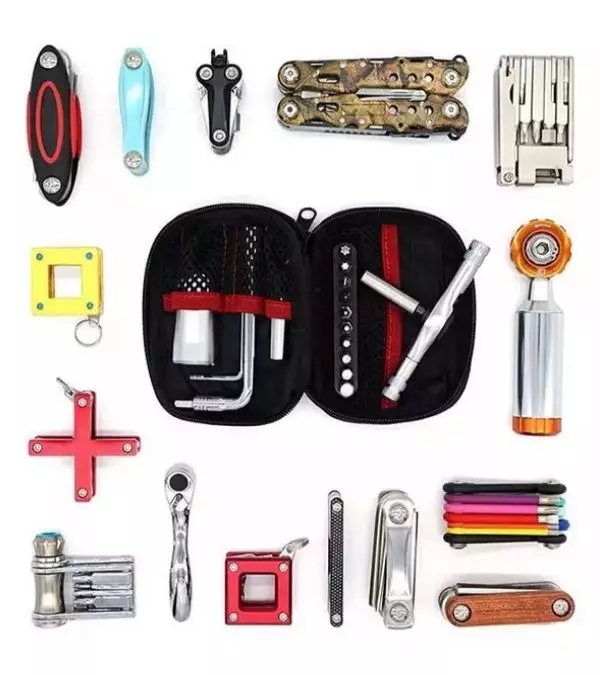

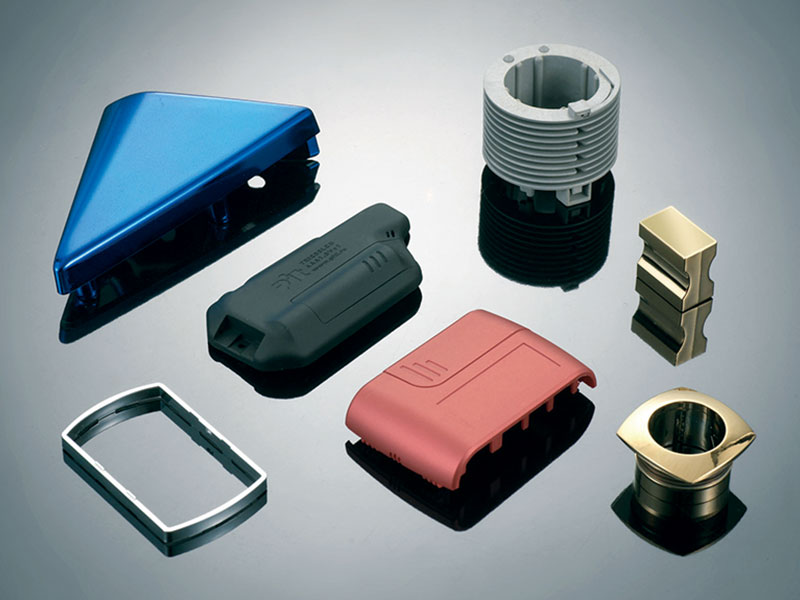

Below are some of our products which go through different surface treatments.

- Gallery

Surface Treatment Manufacturer | Pan Taiwan

Located in Taiwan since 1977, Pan Taiwan Enterprise Co., Ltd. has been a manufacturing process services provider. Our main manufacturing process services include, Surface Treatment, tactical bags manufacturing, custom bike frames, custom carbon fiber products, multi-tools, custom plastic injection parts, product assembly, reverse engineering, investment casting parts, machined parts, sheet metal stamping, bike caps, which have ISO 9000 and ISO 13485 quality assurance certifications.

Pan Taiwan with certified ISO 9001 provides manufacturing services and total solutions for anyone who has any custom parts in need we have sophisticated experiences to partner with a wide range of manufacturers from Plastic Injection, Die Casting, Forging, CNC machining, Tactical Bags, EDC pouches or standard bicycle and outdoor activity parts for nearly 50 years, so we will act as your eyes and ears for any project you have with us. We don't just supply bicycle parts, accessories, and carabiners in multiple applications. We also offer OEM and ODM services to make your idea come true. The manufacturing processes we're good at are plastic injection, sheet metal stamping, investment casting, MIM and many more.

Pan Taiwan has been offering customers manufacturing process services, both with advanced technology and 50 years of experience, Pan Taiwan ensures each customer's demands are met.