Quality Assurance and Quality Control

Pan Taiwan Quality Assurance and Quality Control System

Since 1996, Pan Taiwan has held ISO 9000 certification. Beyond adhering to ISO standards, we differentiate ourselves with two key policies: continuous improvement of our quality procedures year after year and ensuring that all staff thoroughly understand ISO requirements as well as our Quality Procedures (QP), applying them in their daily work. Furthermore, each employee undergoes 4-hour training courses twice to become internal auditors. All our QC equipment is regularly calibrated by certified laboratories.

Comprehensive Quality Control for Our Products

Our dedicated QC department inspects goods following the working instructions issued by the R&D department and records the results meticulously. QC personnel also check specific points highlighted by the sales team to meet customers' special requirements. Typically, we adhere to Pan Taiwan Acceptable Quality Level (PT AQL), but we are flexible to follow higher standards if specified by our customers. For custom-developed products, we maintain approved samples as golden samples for production reference. Additionally, we archive samples from each shipment to verify quality issues, should they arise from production or customer feedback.

Detailed Inspection Reports and Continuous Improvement

Our inspection reports are typically written in Chinese; however, English versions are available upon request. This ensures transparency and clarity for our international clients. By continuously enhancing our quality assurance processes and maintaining rigorous standards, we guarantee the highest level of quality control for all our products.

- Shipping Sample Archive.

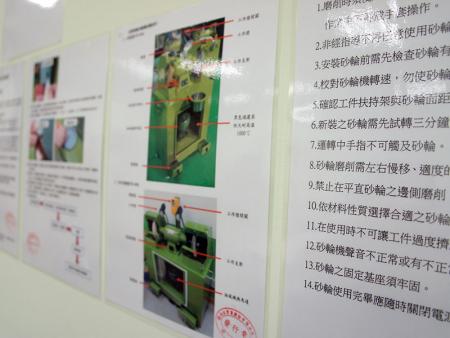

- Our quality procedure documents.

- Inspection report in Chinese.

- English inspection report is available upon your request.

- Procedure documents is put up at the work place.

- Our QC department check on over 1000 shipments every year.

- Files Download