Metal Injection Molding

Metal parts injection molding service

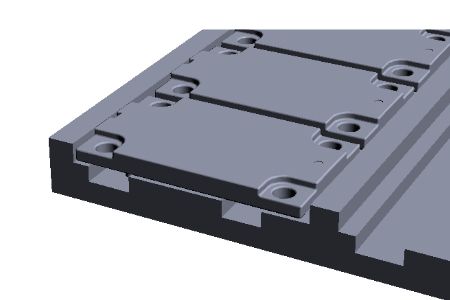

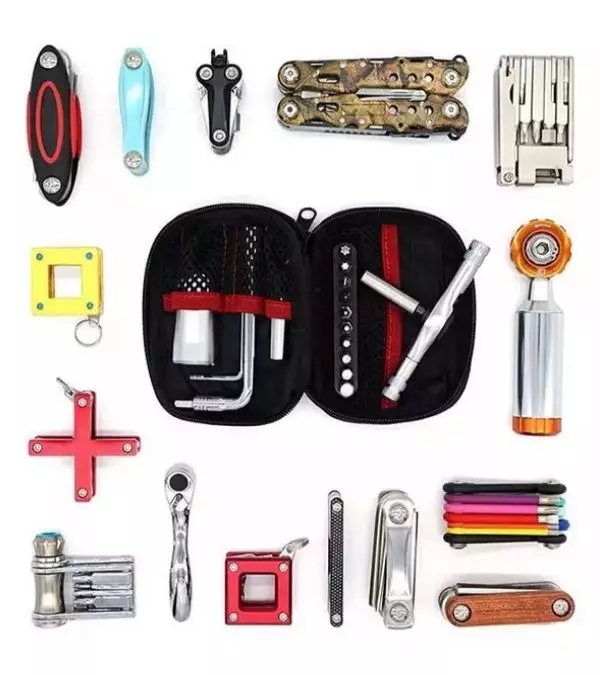

As a skilled Metal Injection Molding supplier in Taiwan, we have helped to manufacture countless delicate parts like handcuff in the United State and camera slide lock pads in Australia. Apart from that, printing stamps, hardware parts, automotive accessories, motor parts and watches in the daily life or pistol components, medical equipment and even your 3C products are all in our Metal Injection Molding process.

The main consideration of metal injection molding part is higher strength and does not require post-process compared with other manufacturing processes for metal parts and our expertise allows us to have quick feedback on the metal design so that your metal part could sit on the fixture properly and will not be deformed during the final sintering process.

Design For Manufacturing Analysis

The metal parts manufactured by Metal Injection Molding usually in complex shape and needs in high strength, therefore, our R&D department provides DFM (Design For Manufacturing) for Metal Injection Molding process which not only review your metal parts drawing and provide summary on the design in order to have better yield rate during metal injection process but also have high efficiency on the communication with you to shorten times to release the parts in the market earlier.

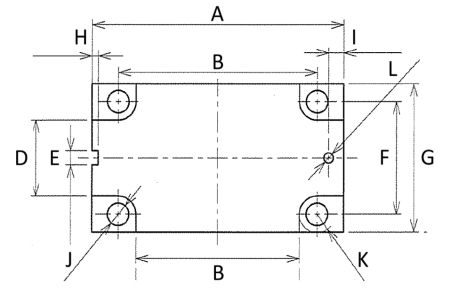

Molding Structure Checking For Metal Parts

To Analyze your design of metal parts and will have further discussion with you for the proper location of the Parting Line and Gate and the Type of the injection gate so that those marks could be hidden to have better aesthetic on the outward.

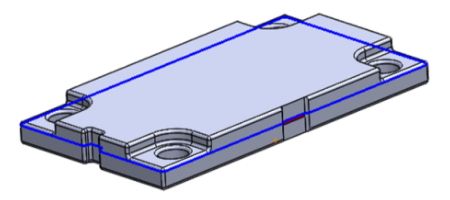

Metal Parts De-Molding

Metal injection molding actually does not require the draft angle but we will still review your 3D drawing and suggest the location for the Ejector Pin to leave the marks inwards or away from functional, aesthetic concern on your metal parts.

Sagging Prevention For Metal Parts

The biggest challenge for metal injection molding part is deformation because the injected metal piece will be about 20% larger than final metal part and potential issue of sink, warpage and shrinkage emerged after sintering process, so our engineers will need to estimate if the drawing could be feasible perfectly or recommend to have uniform wall thickness or design the fixture accordingly to hold your metal parts in position so that to achieve the higher yield rate.

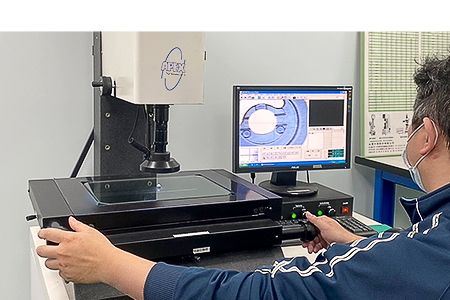

Metal Injection Parts Inspection

Metal injection parts are usually small, delicate and in high complexity, so we will work with you where are the critical points for the measurement then our QC team will follow this instruction and inspect your metal parts accordingly by 2.5D CCD Optical Projector or Caliper then documented in our inspection reports to make sure your MIM parts are good to go and will keep shipping samples in our sample archive for the traceability of each batch.

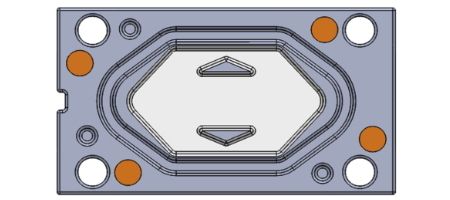

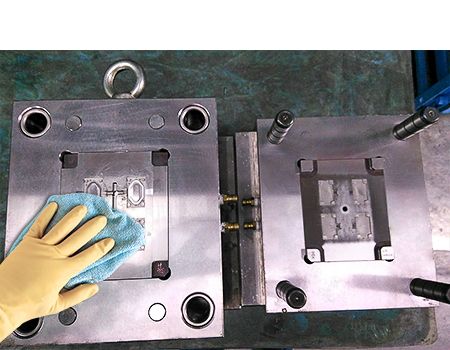

Metal Injection Tooling Maintenance

The material for metal injection tooling, usually is JIS S50C for the mold base and JIS SKD11 for the mold cores if there is no specific requirement on the tooling. The life cycle of metal injection molding varies and depends on the complexity of the metal parts you designed but generally speaking, it would be approximately 100,000 to 300,000 shots of molding and we will disassemble the whole metal injection tooling and clean all components of mold after each production or quickly maintain the surface of tooling periodically to keep the life span of tooling longer. We will also keep monitoring the metal injection tooling when shots of molding reached the end of life span and notify you the final tooling status so that you will be able to know if tooling is still workable or not. For more information, you may feel free to send our inquiry down below and we will take care of it shortly.

Whether you’re prototyping a new design or scaling up for production, our rubber molding capabilities are engineered to deliver precision, reliability, and speed.

Metal Injection Molding Manufacturer | Pan Taiwan

Located in Taiwan since 1977, Pan Taiwan Enterprise Co., Ltd. has been a manufacturing process services provider. Our main manufacturing process services include, Metal Injection Molding, tactical bags manufacturing, custom bike frames, custom carbon fiber products, multi-tools, custom plastic injection parts, product assembly, reverse engineering, investment casting parts, machined parts, sheet metal stamping, bike caps, which have ISO 9000 and ISO 13485 quality assurance certifications.

Pan Taiwan with certified ISO 9001 provides manufacturing services and total solutions for anyone who has any custom parts in need we have sophisticated experiences to partner with a wide range of manufacturers from Plastic Injection, Die Casting, Forging, CNC machining, Tactical Bags, EDC pouches or standard bicycle and outdoor activity parts for nearly 50 years, so we will act as your eyes and ears for any project you have with us. We don't just supply bicycle parts, accessories, and carabiners in multiple applications. We also offer OEM and ODM services to make your idea come true. The manufacturing processes we're good at are plastic injection, sheet metal stamping, investment casting, MIM and many more.

Pan Taiwan has been offering customers manufacturing process services, both with advanced technology and 50 years of experience, Pan Taiwan ensures each customer's demands are met.