Injection & Molding Services

Pan Taiwan offers OEM/ODM injection molding services specializing in plastic, rubber, and metal...

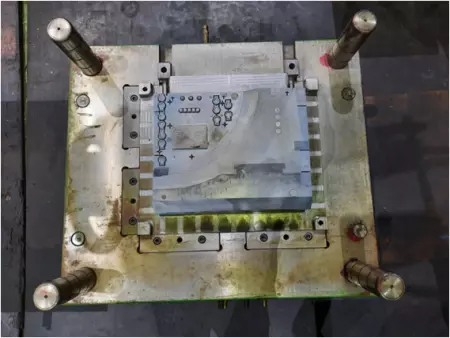

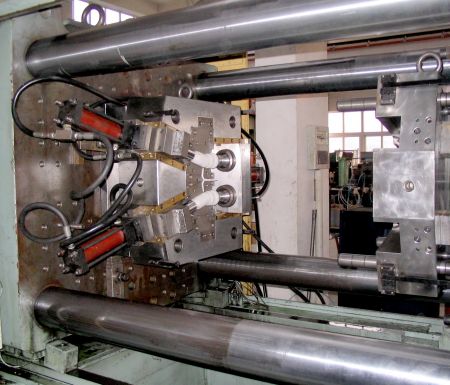

Plastic Injection molding service

Pan Taiwan specializes in plastic injection molding services, offering customized solutions...

Rubber Molding

We provide comprehensive rubber molding solutions tailored to diverse industrial needs. Our capabilities...

Metal Injection Molding

As a skilled Metal Injection Molding supplier in Taiwan, we have helped to manufacture countless...

Compression Molding

There are many fabrication processes to create carbon fiber parts, here at Pai Taiwan(OEM),...

Hand Lay-up Process

Pan Taiwan provides custom carbon fiber manufacturing process - hand lay-up process. Hand lay-up...

Vacuum Bagging

Pan Taiwan provides custom carbon fiber parts made by vacuum bagging. The mold cost is lower...

LSR Molding

Apart from Rubber Molding, Pan Taiwan also offers LSR (Liquid Silicone Rubber) Molding service...

Rubber Injection Molding

We specialize in rubber injection molding, offering stable and high-precision production capabilities...

Transfer Molding

Besides rubber molding, Pan Taiwan can also offer transfer molding service. The transfer molding...

Plastic Insert Molding Service

Plastic insert molding combines two different materials like plastic injection and metal insert...

Plastic Over molding Service

Plastic over molding is a versatile manufacturing process that bonds two different resins into...