Casting Manufacturing Service

Precision Metal Casting & Integrated Manufacturing Solutions

We aim to provide precision casting service with integrated manufacturing service, which includes form mold design, mass production, post-manufacture service, and surface treatment. With decades of experience in the field, we have managed and held a strong connection with our supplier network. We are able to adapt different methods and strategies that fit and optimize your production flow to meet the balance of efficiency, quality, and cost—the "golden triangle" that matters the most in a strong and striving business model.

Core Capabilities

We offer robust casting and finishing solutions using advanced equipment and established processes.

Casting Manufacture

We utilize a diverse range of casting methods tailored to project needs. Our primary offerings include:

- Aluminum & Zinc Die Casting: Our high-pressure machines range from 150 tons – 900 tons, making them suitable for mid-to-large size items.

- Investment Casting: This lost wax process is ideal for components requiring highly complex geometry and high precision, best suited for small batch customization.

- Sand Casting: A versatile method ideal for producing larger parts and small to medium production runs.

- Gravity Casting (Permanent Mold): Offers a balance between the precision of die casting and the flexibility of sand casting, producing denser and higher-integrity parts.

Secondary Processes & Finishing

Beyond primary casting, we provide essential secondary refinement services. We offer necessary CNC precision finishing using 5-axis machines and turning-milling compound machines to meet the required small tolerances and high precision after the casting process. We also integrate other manufacturing processes such as stamping and extrusion, depending on your specific requirements.

Post-Manufacture Services & Surface Treatment

We provide comprehensive post-production services to finalize and enhance your components. Our available surface treatments include anodizing, electroplating, powder coating, sandblasting, vibratory finishing, and pickling. We also manage item assembly, conduct quality checks, and handle logistic allocation to streamline your supply chain.

Material and Applications

We utilize industry-standard materials for a wide variety of product applications.

Material Used

We commonly work with aluminum alloys like ADC12, A380, A356.2 (cast grade), and A360, as well as various grades of stainless steel and carbon steel.

Application Sectors

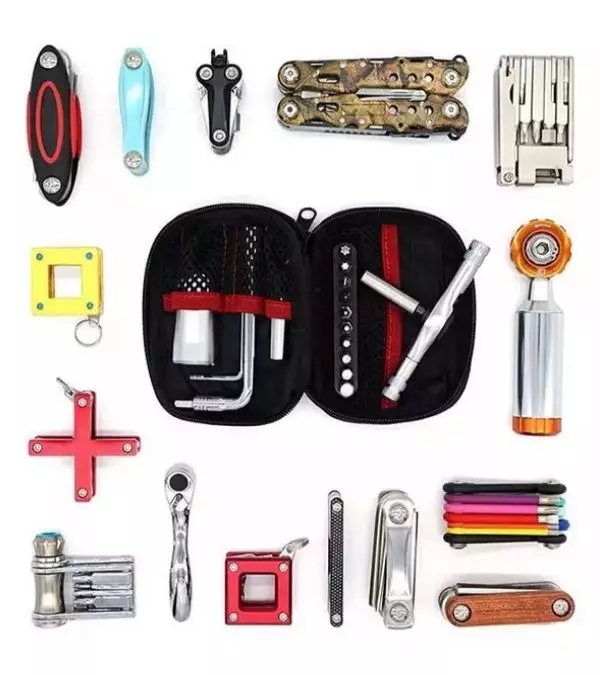

Our components are used across diverse sectors, including automotive parts, communication devices, medical devices, industrial components, and consumer goods.

Quality and Management

Our operations adhere to stringent quality and environmental standards.

- ISO9001, IATF16949, and ISO14001 certifications for management and environment.

- Utilization of PDCA cycles, Management by Objectives (MBO), and mold flow analysis to ensure process stability and quality consistency

Explore our casting process pages to learn how we take your design from concept to finished product. Contact Pan Taiwan for reliable, export-ready casting solutions.

Aluminum / Zinc Die Casting

At Pan Taiwan, we specialize in aluminum and zinc die casting, delivering both bare casting...

DetailsInvestment Casting Service

Investment casting is a precise casting manufacturing process that allows to create intricate...

DetailsSand Casting

Pan Taiwan is a well-developed manufacturer of sand casting. We provide a variety of post process...

DetailsGravity Casting

Pan Taiwan is sophisticated in the characteristics of various aluminum alloy materials and to be proud...

DetailsCasting Manufacturing Service Manufacturer | Pan Taiwan

Located in Taiwan since 1977, Pan Taiwan Enterprise Co., Ltd. has been a manufacturing process services provider. Our main manufacturing process services include, Casting Manufacturing Service, tactical bags manufacturing, custom bike frames, custom carbon fiber products, multi-tools, custom plastic injection parts, product assembly, reverse engineering, investment casting parts, machined parts, sheet metal stamping, bike caps, which have ISO 9000 and ISO 13485 quality assurance certifications.

Pan Taiwan with certified ISO 9001 provides manufacturing services and total solutions for anyone who has any custom parts in need we have sophisticated experiences to partner with a wide range of manufacturers from Plastic Injection, Die Casting, Forging, CNC machining, Tactical Bags, EDC pouches or standard bicycle and outdoor activity parts for nearly 50 years, so we will act as your eyes and ears for any project you have with us. We don't just supply bicycle parts, accessories, and carabiners in multiple applications. We also offer OEM and ODM services to make your idea come true. The manufacturing processes we're good at are plastic injection, sheet metal stamping, investment casting, MIM and many more.

Pan Taiwan has been offering customers manufacturing process services, both with advanced technology and 50 years of experience, Pan Taiwan ensures each customer's demands are met.