Investment Casting Service

Lost-wax casting

Investment casting is a precise casting manufacturing process that allows to create intricate shape for your metal parts and achieve the complex designs easily compared with other casting methods. We have experienced in manufacturing investment casting and will review your drawing then quick feedback on our Design For Manufacturing to bring you more clear picture how we could make your investment casting parts more producible with lower defeat and better aesthetic improvement.

Benefits Of Investment Casting

Investment casting provides several benefits compared with other casting methods, like design flexibility to allow your investment casting parts have much more complex shapes and intricate details; excellent surface finish and tight tolerances to lead your investment casting parts to have smooth surfaces, fine details and less post-process requirement to have better aesthetics plus high accuracy and consistency; wide material selection for you to choose for your investment casting parts from carbon steel, stainless steel, aluminum alloy, copper castings, etc. then finally, investment casting is particularly well suited for small to medium production runs and relatively low cost on the mold so that it will be the most cost effective option for your investment casting parts.

Application for your investment casting parts

- Investment casting parts could be utilized widely in various industries, including:

- Automobile

- Medical equipment

- Aerospace

- Jewelry

- Computer peripheral

- Lifting device

- Hardware

For more information on our Design For Manufacturing service, you might kindly check it on our other pages under the selection of Total solution page or if any new project of investment casting is waiting for further evaluation, please send us the Product Inquiry down below then our sale representative will take care of it within a working day.

Investment Casting Service Manufacturer | Pan Taiwan

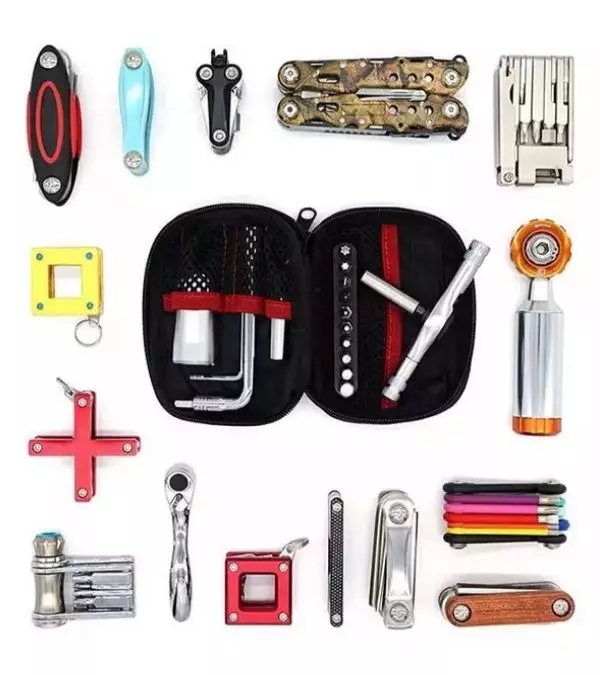

Located in Taiwan since 1977, Pan Taiwan Enterprise Co., Ltd. has been a manufacturing process services provider. Our main manufacturing process services include, Investment Casting Service, tactical bags manufacturing, custom bike frames, custom carbon fiber products, multi-tools, custom plastic injection parts, product assembly, reverse engineering, investment casting parts, machined parts, sheet metal stamping, bike caps, which have ISO 9000 and ISO 13485 quality assurance certifications.

Pan Taiwan with certified ISO 9001 provides manufacturing services and total solutions for anyone who has any custom parts in need we have sophisticated experiences to partner with a wide range of manufacturers from Plastic Injection, Die Casting, Forging, CNC machining, Tactical Bags, EDC pouches or standard bicycle and outdoor activity parts for nearly 50 years, so we will act as your eyes and ears for any project you have with us. We don't just supply bicycle parts, accessories, and carabiners in multiple applications. We also offer OEM and ODM services to make your idea come true. The manufacturing processes we're good at are plastic injection, sheet metal stamping, investment casting, MIM and many more.

Pan Taiwan has been offering customers manufacturing process services, both with advanced technology and 50 years of experience, Pan Taiwan ensures each customer's demands are met.