Tactical Bags Manufacturing

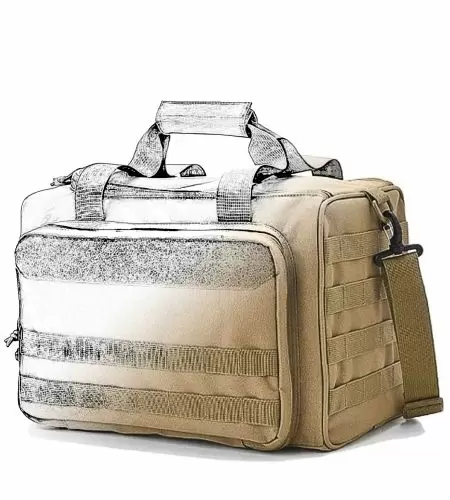

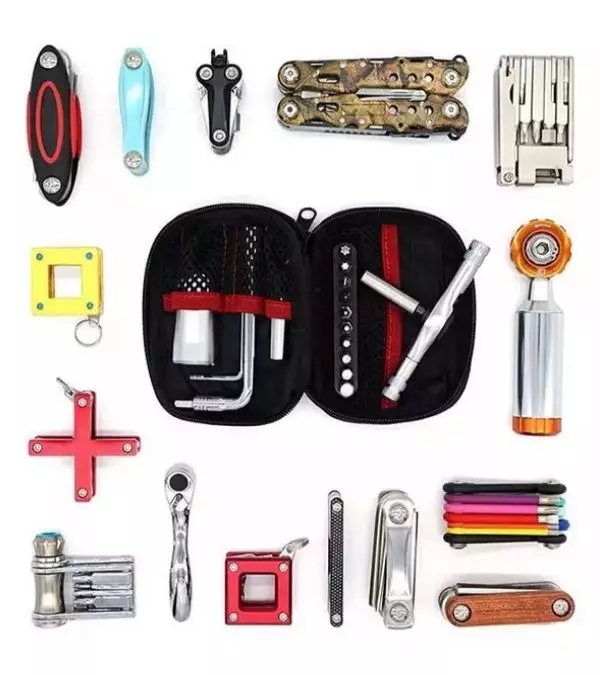

Customized tactical bags, hunting backpacks, and EDC pouches for outdoor professionals.

Welcome to Pan Taiwan's world of tactical bag manufacturing. We specialize in custom OEM production, no off-the-shelf products, no compromises. Whether you're sourcing for field deployment, private label branding, or industrial use, our build-to-order approach ensures your design fits perfectly.

Tailored to Perfection for Your Brand

Your vision. Your design. Pan Taiwan brings it to life. From large game backpacks and tactical bags to modular field packs, we manufacture strictly according to your specifications. Every detail matters-from material selection to functional layout. We also offer proactive design suggestions to help maximize performance and value. Our services are tailored for brands, distributors, and procurement teams seeking scalable solutions.

- MOQ: 600pieces

- Support includes: Branding, packaging, and R&D collaboration

- Production: Bulk only, no retail

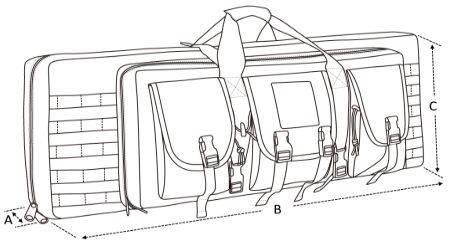

Tactical Bag Manufacturing Process Overview

To ensure optimal results, please include the following in your tactical bag design file or sketch:

- Dimensions

- Intended functionalities

- Preferred materials

- Target user scenario or work environment (if applicable)

Once received, our R&D team will carefully review your file and provide feedback to enhance manufacturability and performance. All final decisions remain entirely in your hands.

Material & Component Selection

Material choice defines performance. Pan Taiwan works with trusted brands and proven patterns known for durability tactical reliability, and outdoor use. Below are commonly requested options—additional materials are available upon request.

Camouflage & Branded Patterns

- MULTICAM® (Crye Precision licensed)

- Coyote Brown (military-standard earth tone)

- Cordura® (solid colors and printed camo)

Material Options

- Nylon (500D/1000D)

- Polyester

- Synthetic Leather

- TPU (Thermoplastic Polyurethane)

- PU (Polyurethane)

- PVC (Polyvinyl Chloride)

Branding Options

Pan Taiwan offers multiple branding methods to elevate your tactical gear. You may apply multiple tags or logos, depending on your product type, OEM design, and branding strategy.

Available Methods

- Rubber Patch

- Embroidery

- Nameplates

- Heat Transfer / Screen Printing

Please send your logo or tag file in .AI format for evaluation. Versatile placement options are available to enhance brand visibility and recognition.

Prototyping & Quick Feedback

Our mission is to deliver total solutions—transforming your designs into reality with precision and care. Our R&D specialists conduct a meticulous review of your design file to ensure seamless integration and optimal performance. We proactively identify potential manufacturing risks and offer tailored recommendations to support your strategic decision-making.

Quality Control

Every batch undergoes rigorous inspection. Critical areas, such as water resistance, stitching integrity, and internal layout—are documented in our tactical gear inspection report.

For specialized quality verification (e.g., lab-certified material testing, waterproof rating validation, or environmental durability assessments), additional costs may apply. These procedures are conducted through accredited third-party institutions. We'll coordinate accordingly and provide transparent quotations based on your project needs.

Bring Your Tactical Vision to Life

Whether you're developing a custom tactical bag, large game backpack, or lightweight hunting pouch, Pan Taiwan is ready to turn your concept into reality. We focus exclusively on OEM customization—no off-the-shelf products, no compromises. Send us your design file or sketch, and our team will collaborate with you to refine every detail for manufacturability, performance, and brand alignment.

Contact us below to start your project.

- Gallery

Tactical Bags Manufacturing Manufacturer | Pan Taiwan

Located in Taiwan since 1977, Pan Taiwan Enterprise Co., Ltd. has been a manufacturing process services provider. Our main manufacturing process services include, Tactical Bags Manufacturing, tactical bags manufacturing, custom bike frames, custom carbon fiber products, multi-tools, custom plastic injection parts, product assembly, reverse engineering, investment casting parts, machined parts, sheet metal stamping, bike caps, which have ISO 9000 and ISO 13485 quality assurance certifications.

Pan Taiwan with certified ISO 9001 provides manufacturing services and total solutions for anyone who has any custom parts in need we have sophisticated experiences to partner with a wide range of manufacturers from Plastic Injection, Die Casting, Forging, CNC machining, Tactical Bags, EDC pouches or standard bicycle and outdoor activity parts for nearly 50 years, so we will act as your eyes and ears for any project you have with us. We don't just supply bicycle parts, accessories, and carabiners in multiple applications. We also offer OEM and ODM services to make your idea come true. The manufacturing processes we're good at are plastic injection, sheet metal stamping, investment casting, MIM and many more.

Pan Taiwan has been offering customers manufacturing process services, both with advanced technology and 50 years of experience, Pan Taiwan ensures each customer's demands are met.