Roll Wrapping

Carbon fiber tube in Pan Taiwan are made by roll wrapping, this manufacturing process is typically done with a prepreg product to unsure consistency and can be customized with different thicknesses, lengths and diameters. The prepreg material is cut into layers of different fiber direction. The layers are then rolled onto a cylindrical rod. The rod and prepreg on it will then be sent into the curing oven. Once curing is complete, the rod is removed from the center of the carbon fiber tube. After the post-process such as machining, polishing and clear varnish, the carbon fiber tube is complete.

Pan Taiwan produce carbon fiber tubes according to customer's drawing and requirements. As a result of our rich experiences, we work with all kinds of materials to create tubes with fiberglass/carbon combinations, carbon fabric, etc. 3K, 12K, UD carbon fiber rods tubes or small production runs are available in Pan Taiwan.

We would love the opportunity to work with you on a custom roll-wrapped product.

What Applications Are Suitable To Use Compression Molding?

Not like compression molding which can produce complex products, roll wrapping is usually used for round and shaped composite tubing. The applications such as bicycle, fishing, archery, etc.

Roll Wrapping Manufacturer | Pan Taiwan

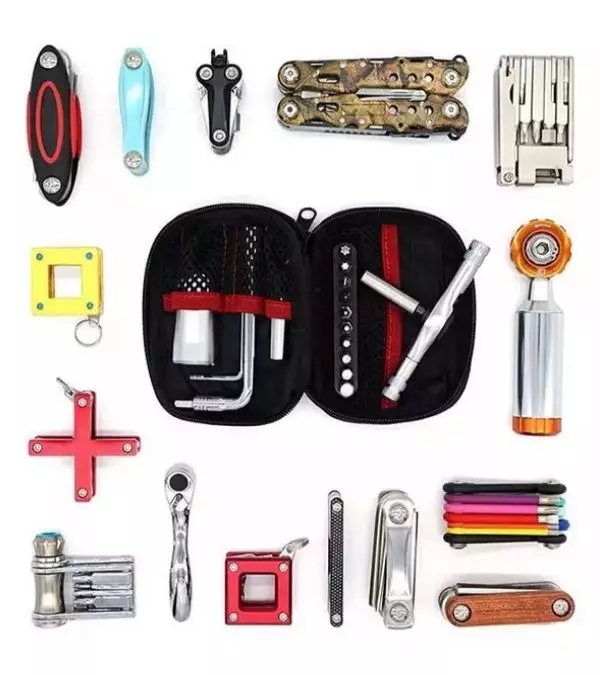

Located in Taiwan since 1977, Pan Taiwan Enterprise Co., Ltd. has been a manufacturing process services provider. Our main manufacturing process services include, Roll Wrapping, tactical bags manufacturing, custom bike frames, custom carbon fiber products, multi-tools, custom plastic injection parts, product assembly, reverse engineering, investment casting parts, machined parts, sheet metal stamping, bike caps, which have ISO 9000 and ISO 13485 quality assurance certifications.

Pan Taiwan with certified ISO 9001 provides manufacturing services and total solutions for anyone who has any custom parts in need we have sophisticated experiences to partner with a wide range of manufacturers from Plastic Injection, Die Casting, Forging, CNC machining, Tactical Bags, EDC pouches or standard bicycle and outdoor activity parts for nearly 50 years, so we will act as your eyes and ears for any project you have with us. We don't just supply bicycle parts, accessories, and carabiners in multiple applications. We also offer OEM and ODM services to make your idea come true. The manufacturing processes we're good at are plastic injection, sheet metal stamping, investment casting, MIM and many more.

Pan Taiwan has been offering customers manufacturing process services, both with advanced technology and 50 years of experience, Pan Taiwan ensures each customer's demands are met.