Cold Forging

Cold forging is a precision metal forming process performed at or near room temperature. It involves compressing metal blanks or wire into dies using high pressure mechanical or hydraulic press. Unlike thermal based methods, cold forging reies on the material's plasticity and controlled deformation to achieve desired shape.

This process is widely used for producing high volume, high strength components such as fasteners, shafts, bushings, and pins. It offers excellent repeatability, surface finish, and dimensional control making it ideal for industries that demand tight tolerance and cost efficiency.

The advantages of cold forging

- High-dimensional Accuracy: Enables tight tolerances with minimal post-machining, ideal for precision parts.

- Excellent Surface Finish: Produces smooth surfaces with reduced need for secondary finishing or coating.

- Material Strength Enhancement: Work hardening during deformation increases tensile strength and fatigue resistance.

- Reduced Material Waste: Near-net shape forming minimizes scrap, improving material utilization.

- High production Efficiency: Suitable for automated, high-speed production of small to medium-sized components.

Practical Limitaions of Cold Forging

- Tooling Investment: Cold forging requires high-strength dies and press systems. Initial tooling costs are higher, but amortized over volume production.

- Material Suitability: Only ductile metals such as aluminum, low-carbon steel, and select stainless grades are suitable. Brittle or high-hardness alloys may crack under pressure.

- Geometry Constraints: Deep cavities, sharp undercuts, and complex shapes may require multi-stage forming or hybrid processes. Cold forging is best suited for symmetrical or cylindrical parts.

- Internal Stress Accumulation: The work hardening effect increases strength but may introduce residual stress. Stress-relief treatments or post-machining may be necessary depending on the application.

- Press Load Requirements: Cold forging demands high-tonnage presses to overcome material resistance. This affects equipment selection and production planning.

Cold Forging Manufacturer | Pan Taiwan

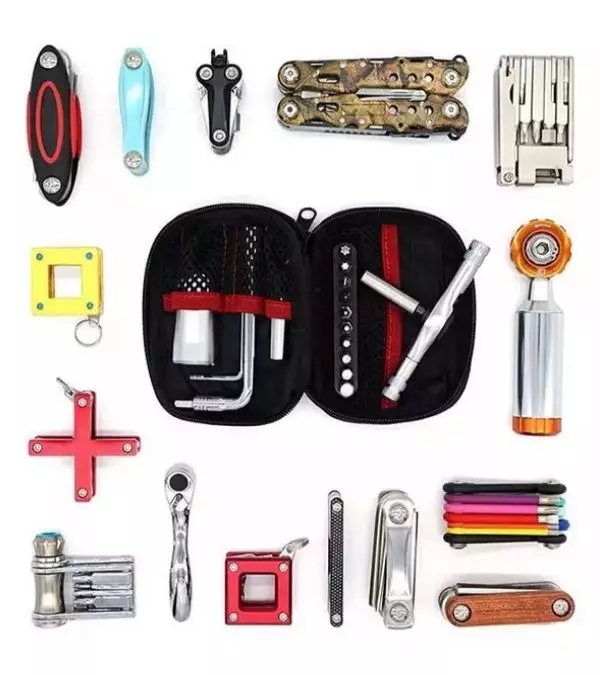

Located in Taiwan since 1977, Pan Taiwan Enterprise Co., Ltd. has been a manufacturing process services provider. Our main manufacturing process services include, Cold Forging, tactical bags manufacturing, custom bike frames, custom carbon fiber products, multi-tools, custom plastic injection parts, product assembly, reverse engineering, investment casting parts, machined parts, sheet metal stamping, bike caps, which have ISO 9000 and ISO 13485 quality assurance certifications.

Pan Taiwan with certified ISO 9001 provides manufacturing services and total solutions for anyone who has any custom parts in need we have sophisticated experiences to partner with a wide range of manufacturers from Plastic Injection, Die Casting, Forging, CNC machining, Tactical Bags, EDC pouches or standard bicycle and outdoor activity parts for nearly 50 years, so we will act as your eyes and ears for any project you have with us. We don't just supply bicycle parts, accessories, and carabiners in multiple applications. We also offer OEM and ODM services to make your idea come true. The manufacturing processes we're good at are plastic injection, sheet metal stamping, investment casting, MIM and many more.

Pan Taiwan has been offering customers manufacturing process services, both with advanced technology and 50 years of experience, Pan Taiwan ensures each customer's demands are met.