Sand Casting

Pan Taiwan is a well-developed manufacturer of sand casting. We provide a variety of post process including machining, sand blasting, plating and etc.

Materials include A356, AC4C, A380, AC7A, and other aluminum alloys. We are capable to produce large aluminum castings. For example, we can produce castings with a weight of 2,000 kg and a length of 5 m x 5 m.

The product range covers mechanical components, automobile and motorcycle parts, air and hydraulic parts, pneumatic tool parts, valves, pumps, motor housings, Various high-quality aluminum castings such as cylinder body, ship parts, furniture and building materials, construction hardware...etc.

Type of Sand Casting

Mechanized Sand Molding

No Baking Molding

Material

A356, AC4C, A380, AC7A... and other aluminum alloy raw materials

Product Features

High strength, corrosion resistance, light weight, high precision.

Advantage of Sand Casting

- Relatively low cost of Mold.

- Suitable for medium and low volume lot size.

- Easily gain small batch of output in short terms.

- Diversified products and high production flexibility.

- Flexible in mechanized or manual production.

Gravity Casting or Sand Casting?

For aluminum alloy casting, sand casting and gravity casting are both very basic production methods, Pan Taiwan’s professional sales team will work out the proposal based on the consideration and comparison of mold cost, lot size, casting size, unit cost, quality criteria, production stability, etc.

Sand Casting Manufacturer | Pan Taiwan

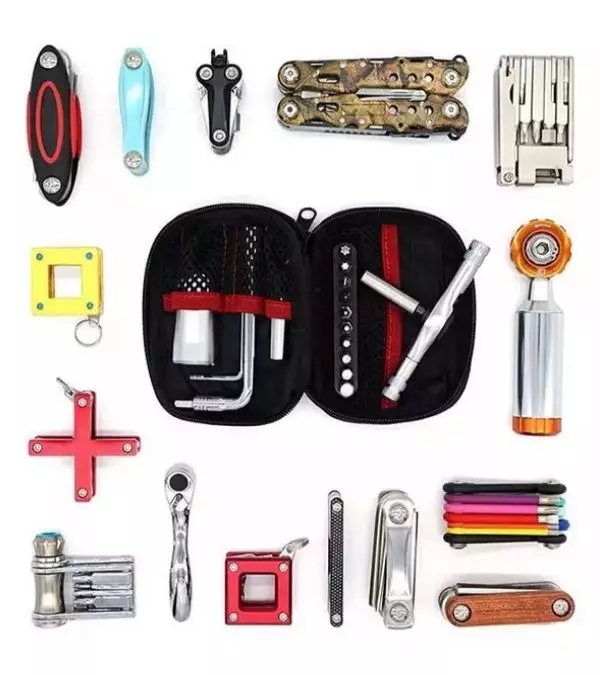

Located in Taiwan since 1977, Pan Taiwan Enterprise Co., Ltd. has been a manufacturing process services provider. Our main manufacturing process services include, Sand Casting, tactical bags manufacturing, custom bike frames, custom carbon fiber products, multi-tools, custom plastic injection parts, product assembly, reverse engineering, investment casting parts, machined parts, sheet metal stamping, bike caps, which have ISO 9000 and ISO 13485 quality assurance certifications.

Pan Taiwan with certified ISO 9001 provides manufacturing services and total solutions for anyone who has any custom parts in need we have sophisticated experiences to partner with a wide range of manufacturers from Plastic Injection, Die Casting, Forging, CNC machining, Tactical Bags, EDC pouches or standard bicycle and outdoor activity parts for nearly 50 years, so we will act as your eyes and ears for any project you have with us. We don't just supply bicycle parts, accessories, and carabiners in multiple applications. We also offer OEM and ODM services to make your idea come true. The manufacturing processes we're good at are plastic injection, sheet metal stamping, investment casting, MIM and many more.

Pan Taiwan has been offering customers manufacturing process services, both with advanced technology and 50 years of experience, Pan Taiwan ensures each customer's demands are met.