Compression Molding

Carbon Fiber Hot Pressing

There are many fabrication processes to create carbon fiber parts, here at Pai Taiwan(OEM), we can provide compression molding process to create advanced carbon fiber parts Compression molding also called hot pressing is a closed-mold composite manufacturing process uses metal molds with high pressure to forming/curing the composite / carbon fiber parts. There are lots of advantages when it comes to compression molding. First of all, comparing to roll wrapping or filament winding, it is more versatile in application, high strength, lighter weight and corrosion resistance. Second, this molding method allows for fibers to be formed into a complex shape. It is something that traditional injection molding method cannot do.

What are main advantages of fabrication parts by compression molding?

The porcess allows us to create complex shape and is suitable for high production volumes. The strength of the products that made by compression molding will be higher than conventional processes such as hand lay-up process. The method are also suitable for high precision products as the method has better dimensional control and stability.

What applications are suitable to use compression molding?

As stated above, the products that have complex shape will benefit from compression molding such as money clip, shift knob, etc. The method is also common for bicycle industry. The carbon fiber bicycle stem that made from compression molding features great strength and lightweight characteristic. Commerical applications like interiors for aircraft and products like trays and panels. Any industries that require complex shaped parts with good mechanical performance, lightweight, anti corrosion features.

Compression Molding Manufacturer | Pan Taiwan

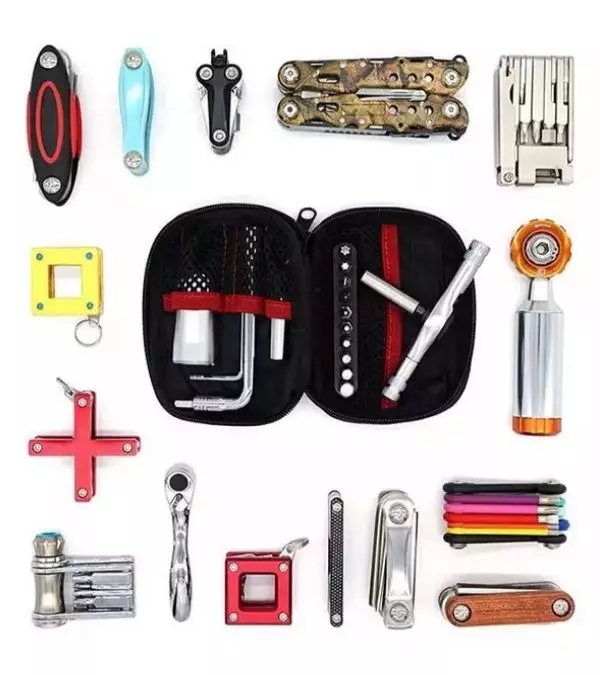

Located in Taiwan since 1977, Pan Taiwan Enterprise Co., Ltd. has been a manufacturing process services provider. Our main manufacturing process services include, Compression Molding, tactical bags manufacturing, custom bike frames, custom carbon fiber products, multi-tools, custom plastic injection parts, product assembly, reverse engineering, investment casting parts, machined parts, sheet metal stamping, bike caps, which have ISO 9000 and ISO 13485 quality assurance certifications.

Pan Taiwan with certified ISO 9001 provides manufacturing services and total solutions for anyone who has any custom parts in need we have sophisticated experiences to partner with a wide range of manufacturers from Plastic Injection, Die Casting, Forging, CNC machining, Tactical Bags, EDC pouches or standard bicycle and outdoor activity parts for nearly 50 years, so we will act as your eyes and ears for any project you have with us. We don't just supply bicycle parts, accessories, and carabiners in multiple applications. We also offer OEM and ODM services to make your idea come true. The manufacturing processes we're good at are plastic injection, sheet metal stamping, investment casting, MIM and many more.

Pan Taiwan has been offering customers manufacturing process services, both with advanced technology and 50 years of experience, Pan Taiwan ensures each customer's demands are met.