Aluminum / Zinc Die Casting

At Pan Taiwan, we specialize in aluminum and zinc die casting, delivering both bare casting parts and full finished components with machining and surface treatment. Whether you're developing mechanical parts or products that demand high-quality surface finishes, our team supports your project from concept to production with precision and consistency.

Aluminum die casting offers lightweight strength and corrosion resistance. Ideal for structural and thermal applications, zinc die casting provides excellent dimensional accuracy and surface detail, making it perfect for small, intricate parts.With both methods, we help you achieve tight tolerances, stable quality in mass production, and the surface performance of your application requires.

Advantages of Pan Taiwan’s Die Casting Service

- DFM (Design for Manufacturing) support to optimize your die cast desings

- Prototype development available for design verification

- Value engineering to reduce cost without compromising quality

- Tight tolerance control through casting and post-machining

- Consistent quality across large-volume production

- Multiple surface finishing options for functional or decorative applications

Surface Treatment recommended for die casting output

- Passivation.

- Phosphating.

- Polishing.

- Liquid / Powder Painting.

- Chrome Plating / E-coating.

Aluminum / Zinc Die Casting Manufacturer | Pan Taiwan

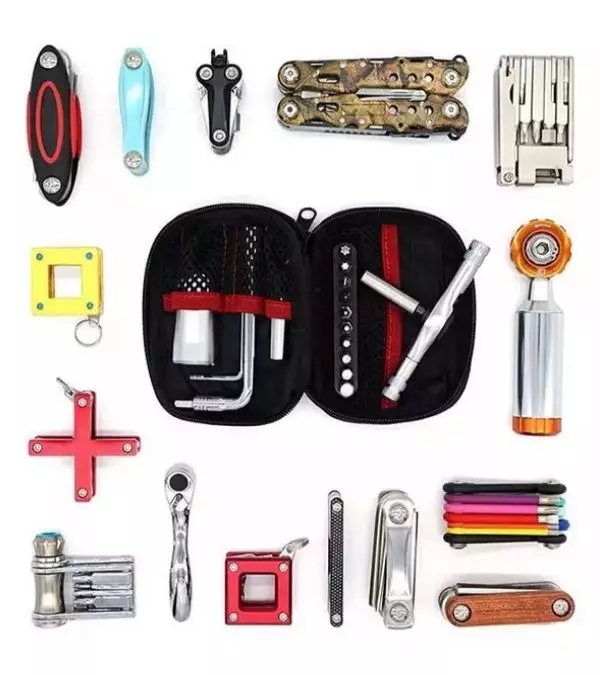

Located in Taiwan since 1977, Pan Taiwan Enterprise Co., Ltd. has been a manufacturing process services provider. Our main manufacturing process services include, Aluminum / Zinc Die Casting, tactical bags manufacturing, custom bike frames, custom carbon fiber products, multi-tools, custom plastic injection parts, product assembly, reverse engineering, investment casting parts, machined parts, sheet metal stamping, bike caps, which have ISO 9000 and ISO 13485 quality assurance certifications.

Pan Taiwan with certified ISO 9001 provides manufacturing services and total solutions for anyone who has any custom parts in need we have sophisticated experiences to partner with a wide range of manufacturers from Plastic Injection, Die Casting, Forging, CNC machining, Tactical Bags, EDC pouches or standard bicycle and outdoor activity parts for nearly 50 years, so we will act as your eyes and ears for any project you have with us. We don't just supply bicycle parts, accessories, and carabiners in multiple applications. We also offer OEM and ODM services to make your idea come true. The manufacturing processes we're good at are plastic injection, sheet metal stamping, investment casting, MIM and many more.

Pan Taiwan has been offering customers manufacturing process services, both with advanced technology and 50 years of experience, Pan Taiwan ensures each customer's demands are met.