Stamping

Metal Stamping Service

Pan Taiwan is specialized in providing precision stamping part for over 50 years. Manufacturing processes we offer are single punch pressing, progressive stamping, regular blanking, fine blanking, threading, piercing, bending, riveting, grinding, rolling, deep drawing, spot welding and assembling. We are also specialized in handling the inner force due to the material characteristics. It usually happens on the products, made from brass or SS301, which have curvy surface or edges.

Material we deal with are carbon steel, galvanized steel, cold rolling steel, stainless steel, aluminum alloy, plastic and copper. We also verify the RoHS compliance status of most of our stamping manufacturing processes and assure to provide the extraordinary service upon RoHS directive requirements. Regarding to finish for the components, we can offer metal polish, mirror polish, anodizing for aluminum alloy, nickel plating, ED and painting.

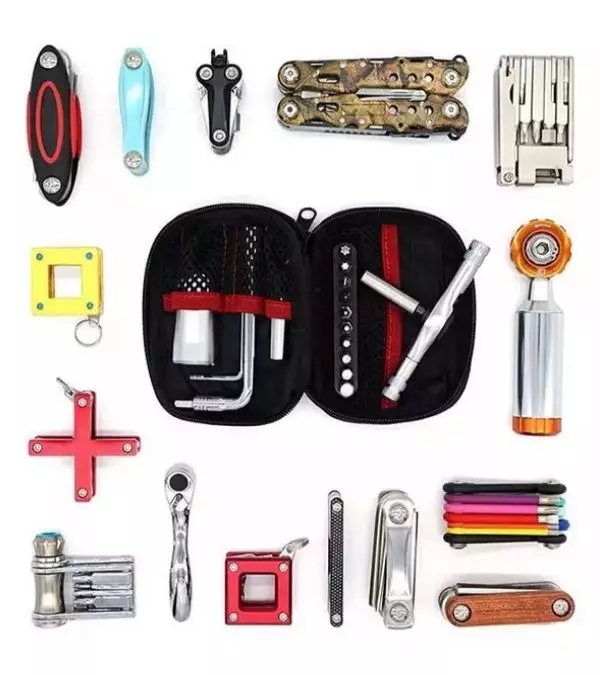

We made components for products such as diving gear buckle, ratchet buckle, fishing gear, pressure gauge, climbing carabiner, car accessories, multi tool, banking printer, motorbike engine cover and food serving cap.

The Materials Listed Below Are Suitable To This Process

- Carbon Steel

- Alloy Steel

- Stainless Steel

- Aluminum Alloy

- Brass

- Copper

Surface Treatmemt Options

- Anodizing

- Powder Coated

- Painting

- Zinc Plate Trivlent Passivate

- Chrome Plate

- Polishing

Application

- Hoist Parts

- Auto Parts

- Outdoor Parts

- Bike Parts

- Funiture Parts

- Foodservice Parts

Below are more products which underwent different stamping processes, click them to know in depth!

Single Punch Press Parts

With 50 years experience, Pan Taiwan is specialized in making stamping parts. Single puch press...

DetailsProgressive Stamping Parts

With 50 years experience, Pan Taiwan are capable to provide you with quality progressive stamping...

DetailsDeep Drawing Parts

Pan Taiwan is a world-class supplier of deep drawing parts. We made caps of cheese shaker,...

DetailsFine Blanking Parts

We can offer quality fine blanking parts without sharp or uneven edge. The maximum of product...

DetailsMore Option for Stamping

Except the previous listed stamping process, we are also capable of serving you process such...

DetailsStamping Manufacturer | Pan Taiwan

Located in Taiwan since 1977, Pan Taiwan Enterprise Co., Ltd. has been a manufacturing process services provider. Our main manufacturing process services include, Stamping, tactical bags manufacturing, custom bike frames, custom carbon fiber products, multi-tools, custom plastic injection parts, product assembly, reverse engineering, investment casting parts, machined parts, sheet metal stamping, bike caps, which have ISO 9000 and ISO 13485 quality assurance certifications.

Pan Taiwan with certified ISO 9001 provides manufacturing services and total solutions for anyone who has any custom parts in need we have sophisticated experiences to partner with a wide range of manufacturers from Plastic Injection, Die Casting, Forging, CNC machining, Tactical Bags, EDC pouches or standard bicycle and outdoor activity parts for nearly 50 years, so we will act as your eyes and ears for any project you have with us. We don't just supply bicycle parts, accessories, and carabiners in multiple applications. We also offer OEM and ODM services to make your idea come true. The manufacturing processes we're good at are plastic injection, sheet metal stamping, investment casting, MIM and many more.

Pan Taiwan has been offering customers manufacturing process services, both with advanced technology and 50 years of experience, Pan Taiwan ensures each customer's demands are met.