ODM Services

ORIGINAL DESIGN MANUFACTURE FOR YOUR TURNKEY PROJECT

Pan Taiwan has a team of engineers who are able to design the products according to your idea and requirements. We have worked with customers and successfully developed the face shield assembly for lumbering. They provide the idea and said the design has to be comparable with 3M product and to pass CE regulation. There are more ODM projects like carbon fiber surfboard and LED sterilization bag are proceeding.

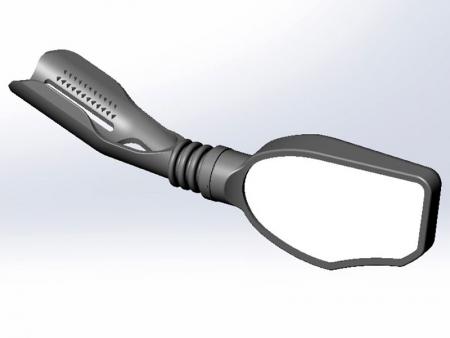

Before we start, we would clarify your requirements to do a sketch so that we can confirm more details including specification from customers. Through some discussion, our engineer made the CAD drawing and the mockup sample for customer’s approval .Furthermore, we will make the prototype according to your approved design to test and to verify its function. As long as customers pay for all the developing cost, they will have the ownership of the product. With the fair contract and agreement, we allow our customer to apply the patent and sell the face shield assembly under their brand.

We would sign NDA as long as the terms are fair to both parties. We always keep projects confidential and select our subcontractors carefully. We will do our best to protect your idea and your intellectual property.

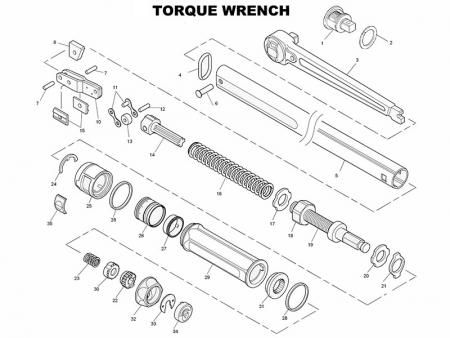

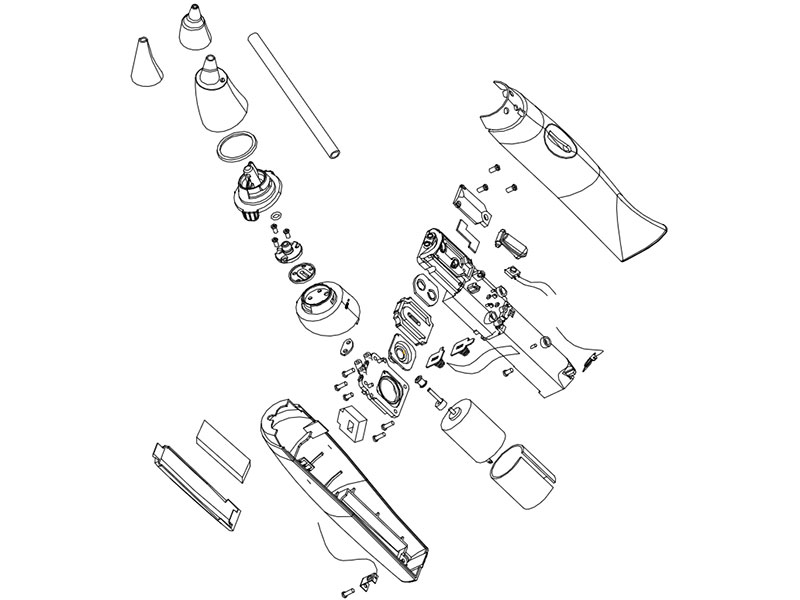

Pan Taiwan's outsourcing service range on product manufacturing is broad, it includes machining, plastic injection, stamping (Blanking, Piercing, Bending, Deep-Drawing, Progressive Stamping, Spot Welding, TIG Welding, Soldering, etc.), forging (Close-Die Forging, Drop Forging, Cold Forging, Cold Heading), casting (Die Casting, Investment Casting (Lost Wax), Gravity Die Casting (Permanent Mold), Sand Casting), rubber molding, MIM(Metal injection molding) and sintering (Powder Metallurgy) on tools, applications, accessories, components, etc. Pan Taiwan takes pride in providing their metalworking outsourcing customers with practical, cost-saving solutions, and market recommendations from a manufacturing perspective.

- Related Products

T Tool Pouch Set

BB50039

It comes with 10 bits and a T way tool all contained in a neat portable pouch. The design of T way tool makes it easy to use while fasten the bolts. Moreover,...

DetailsPlastic Insert Molding Service

Plastic insert molding combines two different materials like plastic injection and metal insert placement into a single step. Plastic insert molding injects...

DetailsRoll Wrapping

Carbon fiber tube in Pan Taiwan are made by roll wrapping, this manufacturing process is typically done with a prepreg product to unsure consistency and can be customized...

Details