Custom Tube Welding

Custom Pipe Fitting Welding

Pan Taiwan (OEM) provides precision custom tube welding solution that use different materials such as Aluminum alloy, Titanium Alloy and Chromoly steel for various application such as bike, outdoor rack and assistive equipment, etc. There are two welding types which are smooth welding and T.I.G Welding made to customers' specification. Pan Taiwan maintains a strong team with R&D and Q/C professionals to ensure quality of products. We highly recognize that weld integrity is the most critical aspect of a welded tube and a good control of the welding process is the key to success.

We are proud of our experience of developing new products in partnership with customers in all industries. Whether your ATV / UTV requires a cargo carriage; rack for carrying boat or canoe on the ATV; mechanical welded parts for assistive equipment; or just custom products rather than standard specification, we offer a comprehensive service to provide engineered solutions.

Not only tubes shaped, we also provide solutions for a broad range of finish, such as painting, plating, printing, PVD coating, ED coating, etc. Our core value is to partner with our customers to create fine products to the markets in every single essential process, including design, development, manufacture and quality control.

The main applications for custom tube welding in Pan Taiwan are Bike frame & fork, bike cargo rack, ATV frame, UTV frame, scooter frame and assistive device for the disable such as wheelchair parts.

With the production facilities both in Taiwan and China, we leave the option to customers for the best combination between the price, quality and the overall performance.

Key factors to have the project succeed:

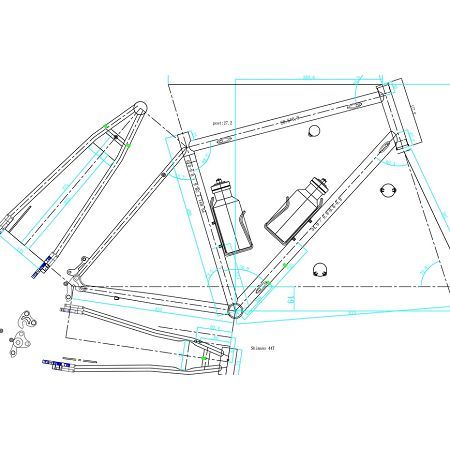

Reviewing drawing & design

Before proceeding with quoting, we will check the drawing and design details based on workability concern. The necessary design change for production concern will be proposed and evaluated. Also the information such as tube material, specification, quantity, tolerance and other requirements will be reviewed in details to make sure the price evaluation is practical.

Tube material and shape options

Different tube shapes offer different property, application and performance. Oval tubes:increase the stiffness along the long axis.Teardrop tubes:make intersection match better and provide greater torsion resistance than conventional round ones.Diamond tubes:increase both lateral and vertical stiffness and perform well in aero-dynamics, the narrow profile presents less frontal surface to the wind which could reduce drag.

Welding, Surface treatment, Heat treatment

We are professional on welding Aluminum Alloy whether you want smooth welding or T.I.G welding, we could do according to customers’ requirement. To offer more service to customers, we are flexible with tooling cost. Building standard spec bike frames or parts that fit our current welding jig and fixture, we won’t take additional cost.

Finish, PVD, Painting and decal

We have partners dealing with painting and decals, and the color guide could be referred to Pantone and YS color code. About Decal, customer’s art work is required to determine the cost according to design complexity, decal size and location.

Assembly service

To offer more services to our customers, take bike as example, we are able to assemble small quantity road bike, MTB, folding bike and recumbent bike for customer. We need specified bike part and accessory specifications then we could quote you with complete bike quotation.

CUSTOM BIKE FRAME SERVICE

Customized bike frames Pan Taiwan offers are Chromoly Steel frame, Titanium Bike Frame and Aluminum Alloy Bike Frame. Pan Taiwan is capable of making small quantity and customized order production. Bike types we deal with are from road bike, MTB, folding bike to recumbent, and we are able to build the customized frames according to your design and drawings. Tube material selections are Aluminum alloy 6061, Chromoly steel 4130 and Titanium seamless tube 3AL2.5V.

CUSTOM ATV FRAME & PARTS

Pan Taiwan is well-experienced in developing and producing the ATV / UTV body parts or supporting frames according to customers’ design or samples.

OFF-THE-SHELF & CUSTOM CAR RACK / CARGO RACK

Pan Taiwan is well-experienced in developing and producing the ATV / UTV body parts or supporting frames according to customers’ design or samples.

ASSISTIVE DEVICES FOR THE DISABLED

Pan Taiwan offers assistive devices and frame such as wheel chair parts according to customers’ design and drawing. Besides, we could also provide painting and logo decals service as long as customers provide the pantone color code and desired logo art work.

Custom Tube Welding Manufacturer | Pan Taiwan

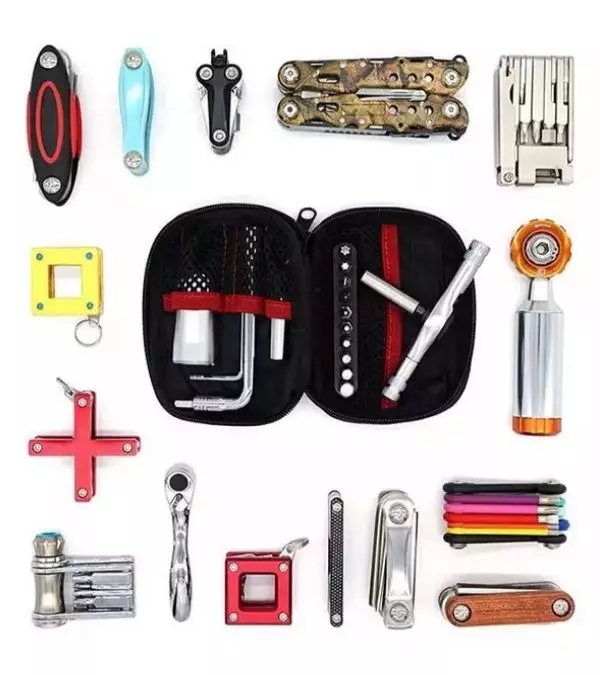

Located in Taiwan since 1977, Pan Taiwan Enterprise Co., Ltd. has been a manufacturing process services provider. Our main manufacturing process services include, Custom Tube Welding, tactical bags manufacturing, custom bike frames, custom carbon fiber products, multi-tools, custom plastic injection parts, product assembly, reverse engineering, investment casting parts, machined parts, sheet metal stamping, bike caps, which have ISO 9000 and ISO 13485 quality assurance certifications.

Pan Taiwan with certified ISO 9001 provides manufacturing services and total solutions for anyone who has any custom parts in need we have sophisticated experiences to partner with a wide range of manufacturers from Plastic Injection, Die Casting, Forging, CNC machining, Tactical Bags, EDC pouches or standard bicycle and outdoor activity parts for nearly 50 years, so we will act as your eyes and ears for any project you have with us. We don't just supply bicycle parts, accessories, and carabiners in multiple applications. We also offer OEM and ODM services to make your idea come true. The manufacturing processes we're good at are plastic injection, sheet metal stamping, investment casting, MIM and many more.

Pan Taiwan has been offering customers manufacturing process services, both with advanced technology and 50 years of experience, Pan Taiwan ensures each customer's demands are met.