Casting Manufacturing Service

Custom Casting Solutions

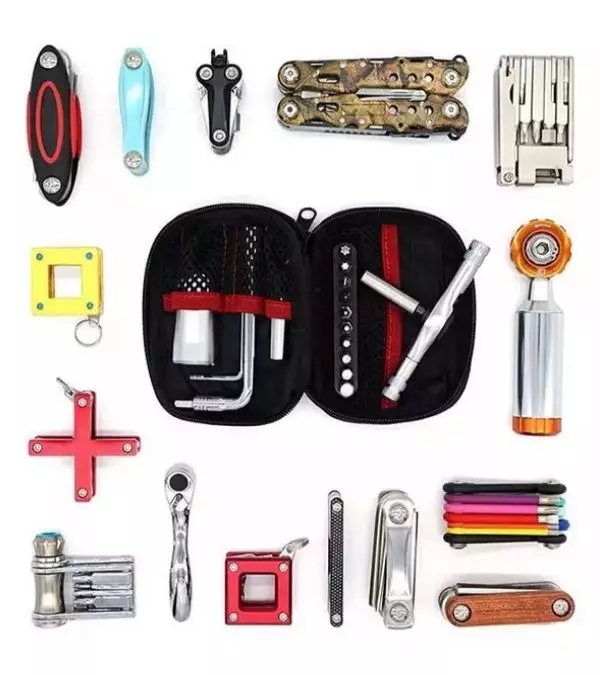

The casting manufacturing services we provide are die casting, investment casting, gravity casting and sand casting which could be applied into wide diversity from lamp stands, furniture, automobile, marine parts, motors, compressors, computer peripherals, locks and even tools for firearms.

As the sophisticated casting manufacturer in Taiwan, we have been supplying casting manufacturing services for various clients in the United State, Europe, and Australia. Apart from that, we are not only providing the casting manufacturing services but also handling post-processing work and surface treatment to make sure your custom casting parts can fit well properly and in good aesthetic condition to be ready to go in the market.

For more detailed information, please feel free to review the following different casting manufacturing pages to make your casting parts step by step into reality with us!

Aluminum / Zinc Die Casting

Pan Taiwan is one of the top die casting part supplier in Taiwan, we are experienced in making...

DetailsInvestment Casting Service

Investment casting is a precise casting manufacturing process that allows to create intricate...

DetailsSand Casting

Pan Taiwan is a well-developed manufacturer of sand casting. We provide a variety of post process...

DetailsGravity Casting

Pan Taiwan is sophisticated in the characteristics of various aluminum alloy materials and to be proud...

DetailsCasting Manufacturing Service Manufacturer | Pan Taiwan

Located in Taiwan since 1977, Pan Taiwan Enterprise Co., Ltd. has been a manufacturing process services provider. Our main manufacturing process services include, Casting Manufacturing Service, tactical bags manufacturing, custom bike frames, custom carbon fiber products, multi-tools, custom plastic injection parts, product assembly, reverse engineering, investment casting parts, machined parts, sheet metal stamping, bike caps, which have ISO 9000 and ISO 13485 quality assurance certifications.

Pan Taiwan with certified ISO 9001 provides manufacturing services and total solutions for anyone who has any custom parts in need we have sophisticated experiences to partner with a wide range of manufacturers from Plastic Injection, Die Casting, Forging, CNC machining, Tactical Bags, EDC pouches or standard bicycle and outdoor activity parts for nearly 50 years, so we will act as your eyes and ears for any project you have with us. We don't just supply bicycle parts, accessories, and carabiners in multiple applications. We also offer OEM and ODM services to make your idea come true. The manufacturing processes we're good at are plastic injection, sheet metal stamping, investment casting, MIM and many more.

Pan Taiwan has been offering customers manufacturing process services, both with advanced technology and 50 years of experience, Pan Taiwan ensures each customer's demands are met.