Precision Machining

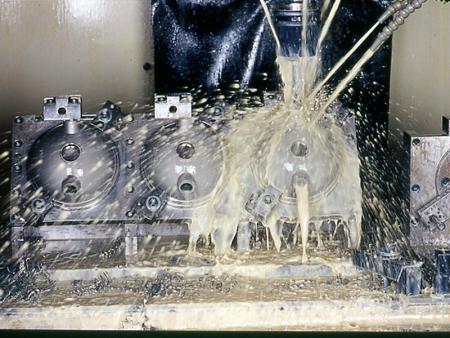

Precision CNC Machining

Over the years we have found that Pan Taiwan is more capable to supply tricky machining parts. Our engineers would try different ways to meet the requirements on the drawing. We have diverse precision 5-axis multitasking center, trun-milling machines, and CNC lathe machines.

The point is to arrange them well with the right cutting tools in the manufacturing procedures to achieve the needs and tolerances of the parts. The dimension we can handle is from OD Ø 2mm to Ø 42mm and the maximum length of 300 mm.

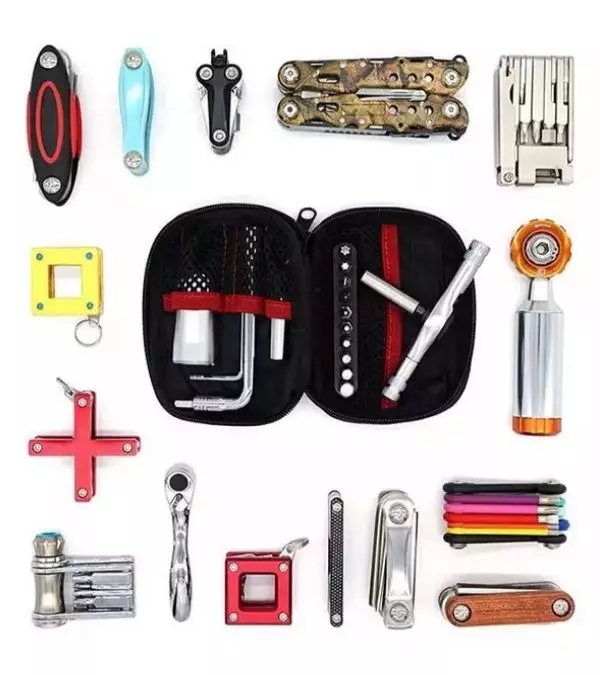

We have executed a diverse type of machining jobs using various materials such as copper, stainless steel, carbon steel and aluminum alloy. We may provide RoHS certificate for brass like C3604, C6801 and C6802. We also have experiences to handle aluminum 7075 and pay attention to the timing to do heat treatment and to anodize the workpiece. We have worked with customers in the fields of high class audio system, gun components, pharmacy equipments, and hand tools. We are able to work with drawings in both ProE and Solidworks files. And additional services such as bending, welding, engraving are also available.

Our 5-Axis Multitasking Center And 8-12 Station High-Rigidity Turrets Machine

Traveling-spindle CNC lathe machines belong to the light cutting process which is generally processed for smaller parts with high accuracy. The length it can handle reaches up to 150mm, and the diameter ranges from 2 mm to 26 mm. Moreover, the materials held by double brake allow more stability which minimize the accuracy to 0.01 mm.

On the other hand, traveling-tool CNC lathe machines belong to the heavy cutting process. The pieces of work are larger in size and their applications could be more than normal ones. The diameter of the pieces ranges from 6mm to 42mm, and the length could be within 100 mm. Even though the materials are heavy, we are also able to make the accuracy less than 5μm.

Multi-Axis CNC Turning & Milling Parts

We can do the multi-axis machining (3-axes, 4-axes and 5 axes), and automatic multi-shaft computerized...

DetailsTurning & Milling Parts

Pan Taiwan is specialized in making Turned / Milled parts according to customers' designs.The...

DetailsPrecision Machining Manufacturer | Pan Taiwan

Located in Taiwan since 1977, Pan Taiwan Enterprise Co., Ltd. has been a manufacturing process services provider. Our main manufacturing process services include, Precision Machining, tactical bags manufacturing, custom bike frames, custom carbon fiber products, multi-tools, custom plastic injection parts, product assembly, reverse engineering, investment casting parts, machined parts, sheet metal stamping, bike caps, which have ISO 9000 and ISO 13485 quality assurance certifications.

Pan Taiwan with certified ISO 9001 provides manufacturing services and total solutions for anyone who has any custom parts in need we have sophisticated experiences to partner with a wide range of manufacturers from Plastic Injection, Die Casting, Forging, CNC machining, Tactical Bags, EDC pouches or standard bicycle and outdoor activity parts for nearly 50 years, so we will act as your eyes and ears for any project you have with us. We don't just supply bicycle parts, accessories, and carabiners in multiple applications. We also offer OEM and ODM services to make your idea come true. The manufacturing processes we're good at are plastic injection, sheet metal stamping, investment casting, MIM and many more.

Pan Taiwan has been offering customers manufacturing process services, both with advanced technology and 50 years of experience, Pan Taiwan ensures each customer's demands are met.